Welcome

to the definitive Chrysler 2.2, 2.5 Non-turbo upgrade database.

Please,

if you have anything you wish to add to this database e-mail me!

This page is for those looking to upgrade their Chrysler TBI or Carbureted

automobile.

Please,

if you have anything you wish to add to this database e-mail me!

This page is for those looking to upgrade their Chrysler TBI or Carbureted

automobile.

A big thanks to

these people that contributed to this database!

Angleo Taylor, Bradley

Miller, Cliff Sebring and Tom Byrne.

See links to their websites

at the bottom of the page.

A big thanks to

these people that contributed to this database!

Angleo Taylor, Bradley

Miller, Cliff Sebring and Tom Byrne.

See links to their websites

at the bottom of the page.

A normally

aspirated engine will generally make less power than a force inducted one

(turbo or supercharged). Your best bet, if you have the cash, is

to swap over to a factory turbo setup. If you cannot, then you have

to live with this limitation and make do with the information on this page..

And

if you don't have a healthy motor you're wasting your time.

Exhaust

A

factory exhaust manifold is fine for most applications. A good cleanup

with a Dremel tool can't hurt here. A header should only be used

for full race applications. It is very impractical for street use,

and generally has a short life.

Some notes from Angelo Taylor...

..these headers are

so long on the four door that sometimes they actually hit the track from

rocking of the motor on

launch, almost always they hit the cross member..

..in under 1 year of street

action they tend to break at the point where they are

welded at the flange..

..The hot ticket is

to get the Mexican stock exhaust header.....it is a tubular one that uses

the

stock donut and attaching

as do ours..

..Another thing on exhaust,

my car always ran a bit

quicker with some type of exhaust on it

compared to open header..

If you

have the money, get a custom 2 1/4" or 2 1/2" system made up with a very

free flowing muffler and cat. If your area allows it or you are using

your car for off road use only, pitch the cat.

Bradley Miller notes..

...I went with 2 1/2

on the Shelby and it picked it up enough that my screwed up feedback carb

caused a lean/bucking condition...

A word on thermal wraps.

I haven't used them on a non-turbo

application, but on my turbo cars we had wrapped the exhaust manifold.

Now Thermo-Tec notes this is a bad thing and they are correct. It

results with a warped, cracked exhaust manifold that flexes so much it

snapped the #1 exhaust stud right out of the head.

proceed at your own risk...

A

factory exhaust manifold is fine for most applications. A good cleanup

with a Dremel tool can't hurt here. A header should only be used

for full race applications. It is very impractical for street use,

and generally has a short life.

Some notes from Angelo Taylor...

..these headers are

so long on the four door that sometimes they actually hit the track from

rocking of the motor on

launch, almost always they hit the cross member..

..in under 1 year of street

action they tend to break at the point where they are

welded at the flange..

..The hot ticket is

to get the Mexican stock exhaust header.....it is a tubular one that uses

the

stock donut and attaching

as do ours..

..Another thing on exhaust,

my car always ran a bit

quicker with some type of exhaust on it

compared to open header..

If you

have the money, get a custom 2 1/4" or 2 1/2" system made up with a very

free flowing muffler and cat. If your area allows it or you are using

your car for off road use only, pitch the cat.

Bradley Miller notes..

...I went with 2 1/2

on the Shelby and it picked it up enough that my screwed up feedback carb

caused a lean/bucking condition...

A word on thermal wraps.

I haven't used them on a non-turbo

application, but on my turbo cars we had wrapped the exhaust manifold.

Now Thermo-Tec notes this is a bad thing and they are correct. It

results with a warped, cracked exhaust manifold that flexes so much it

snapped the #1 exhaust stud right out of the head.

proceed at your own risk...

Intake

TBI:

Work with what you have, it's all you can get. A good clean up with

a Dremel tool to take the rough edges off can't hurt.

Cliff Sebring sent

me a tip...

The carbureted intake

flows better than the TBI one. I had a customer who was running a TBI setup

who adapted a carb intake

to his TBI unit and it went faster.

I'm

checking into the possibility of a spacer under the TBI unit for better

airflow.

Carb:

The 86-up Intake manifolds are the best for general use.

I am

also looking into information on carb spacers.

I had one made of

wood that did not really seem to do anything.....

Mopar

Performance has a dual carb intake as well as a sidedraft Weber setup.

Weber

intake PN: P4349086

...the dual

40 DCOE Weber side draft carbs picked up my car from .75 to around a full

second...

Weber

intake PN: P4349086

...the dual

40 DCOE Weber side draft carbs picked up my car from .75 to around a full

second...

PN:

P4452037

I don't

have any information on the dual carb setup above but will make inquiries.

Note:

this product has been discontinued.

PN:

P4452037

I don't

have any information on the dual carb setup above but will make inquiries.

Note:

this product has been discontinued.

Fred Greer's dual

carbed K-car wagon.

One

easy hp gain is disconnecting the coolant lines running under the

intake for a cooler intake charge. This may cause drivability problems

in cool weather.

You

could also try running water under the intake for an even cooler intake

charge using an electric water pump and a cool can.

Fred Greer's dual

carbed K-car wagon.

One

easy hp gain is disconnecting the coolant lines running under the

intake for a cooler intake charge. This may cause drivability problems

in cool weather.

You

could also try running water under the intake for an even cooler intake

charge using an electric water pump and a cool can.

Camshaft

The

best factory cam would be the 84-87 2.2/2.5 camshaft. It has the

most lift and duration of all the non turbo cams. You can run the

later roller cams if you wish; they do have a little smoother idle and

make less noise but you will lose some duration (240 vs 234). It's

a drop in; just use the roller followers and it will work in any 2.2/2.5

engine.

Non

stock cams may also annoy the computer on TBI applications.

..I suggest a 460/480

lift....any easily available duration.....cam sprocket is another thing...

....the 110 HP HO carb cars

had a cam cog that was 2 degrees different than that of the

regular carb 2.2s......the

visual indication is that the hole on the timing point of the cog is oval

instead of circular..

Tom

Byrne writes into the database...

I run the Mopar Performance

252 cam and it runs great. My car is a 2168 lb 84 Shelby Charger that

is raced SCCA SOLO II class.

Carb is a 5220 Holley, compression is 10:1, head is ported with stock valves

and a 3 angle valve job. Exhaust is a stock manifold with 2 1/2" pipe,

and a Flowmaster race muffler (Straight through design) which exits out

just behind the drivers door.

Pn:

P4529320 Specs: 252-252 duration, 430 lift.

NOTE:

Do NOT use the turbo cams in a non turbo application!! You will lose

horsepower. They have less duration and overlap than their non turbo

cousins.

The

best factory cam would be the 84-87 2.2/2.5 camshaft. It has the

most lift and duration of all the non turbo cams. You can run the

later roller cams if you wish; they do have a little smoother idle and

make less noise but you will lose some duration (240 vs 234). It's

a drop in; just use the roller followers and it will work in any 2.2/2.5

engine.

Non

stock cams may also annoy the computer on TBI applications.

..I suggest a 460/480

lift....any easily available duration.....cam sprocket is another thing...

....the 110 HP HO carb cars

had a cam cog that was 2 degrees different than that of the

regular carb 2.2s......the

visual indication is that the hole on the timing point of the cog is oval

instead of circular..

Tom

Byrne writes into the database...

I run the Mopar Performance

252 cam and it runs great. My car is a 2168 lb 84 Shelby Charger that

is raced SCCA SOLO II class.

Carb is a 5220 Holley, compression is 10:1, head is ported with stock valves

and a 3 angle valve job. Exhaust is a stock manifold with 2 1/2" pipe,

and a Flowmaster race muffler (Straight through design) which exits out

just behind the drivers door.

Pn:

P4529320 Specs: 252-252 duration, 430 lift.

NOTE:

Do NOT use the turbo cams in a non turbo application!! You will lose

horsepower. They have less duration and overlap than their non turbo

cousins.

Cam

keys are a good way to adjust your cam timing.

Shelby

retarded the camshaft 4 degrees in the carburated Shelby Chargers

to make

more high rpm hp.

I prefer

cam keys to "slip-slide" cam sprockets because of cost and its easier to

duplicate results with the cam keys.

PN:

P4349650

Cam

keys are a good way to adjust your cam timing.

Shelby

retarded the camshaft 4 degrees in the carburated Shelby Chargers

to make

more high rpm hp.

I prefer

cam keys to "slip-slide" cam sprockets because of cost and its easier to

duplicate results with the cam keys.

PN:

P4349650

Heads

The best flowing head is the

83-85 "G" casting head. It flows 10% more air than the 86-92 "782"

head which makes about 10% more torque. The "G" head would be a good

choice for a light car, while the "782" or fast burn head will be better

for a heavier vehicle.

Porting and polishing of cylinder

heads is best done by a professional. Unless you have lots of practice

and have done several, it's very easy to damage a head and make it unusable.

Mopar Performance has two

heads in their catalog: a mild ported head with 1 mm oversize valves and

a more extensively ported head with much larger valves. I will try

to get some hp numbers to see how much gain is acquired installing one

of these units.

....I

had a big valve head that was ported and 14/1 compression.....my car runs

quicker with the

stock valved head with a

three angle valve job and 12/1 compression and port matching...

....these cars like

efficiency of flow, not mass of flow on the heads..

LRE and Forward Motion

also have ported heads for sale.

The best flowing head is the

83-85 "G" casting head. It flows 10% more air than the 86-92 "782"

head which makes about 10% more torque. The "G" head would be a good

choice for a light car, while the "782" or fast burn head will be better

for a heavier vehicle.

Porting and polishing of cylinder

heads is best done by a professional. Unless you have lots of practice

and have done several, it's very easy to damage a head and make it unusable.

Mopar Performance has two

heads in their catalog: a mild ported head with 1 mm oversize valves and

a more extensively ported head with much larger valves. I will try

to get some hp numbers to see how much gain is acquired installing one

of these units.

....I

had a big valve head that was ported and 14/1 compression.....my car runs

quicker with the

stock valved head with a

three angle valve job and 12/1 compression and port matching...

....these cars like

efficiency of flow, not mass of flow on the heads..

LRE and Forward Motion

also have ported heads for sale.

The

Short Block

I'm

not going to get into much detail about the various rod/crank/piston combos

that could have been had over the years in the 2.2/2.5 family. Instead

this will be a general tips section on what to do while playing around

the insides of your short block.

It

bears repeating, a healthy motor makes hp- a tired one will not.

If you

have the money and are using your car for pure racing 12.5 to 14:1 compression

seems to be the hot ticket. High-octane race gas of course is required.

For

street use, no more than 9.5:1 is recommended.

Aftermarket

pistons are readily available from TRW, Mopar Performance and J&E Pistons.

Stock

connecting rods are fine, replace the rod bolts with ARP units if

you're having the rods resized (shotpeening is not a bad idea either).

On

oil pressure, experts recommend 7 to 10 psi of oil pressure for every 1000

rpm of engine usage.

7 psi

+ 6000 rpm = 42 psi

10 psi

+ 6000 rpm = 60 psi

Also

make sure you're using Mobil One oil- a synthetic motor oil will make more

hp than a regular oil (frictional gains).

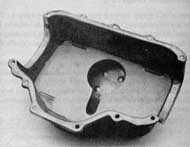

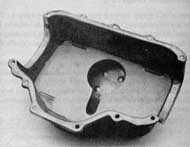

Speaking

of oil, a good baffled oil pan can help keep the oil in the pan where it

belongs. Without one, the crank whips the oil up and costs hp.

On

a 440 Mopar V8 this is good for 15hp at 6000 rpm!

I'm

not going to get into much detail about the various rod/crank/piston combos

that could have been had over the years in the 2.2/2.5 family. Instead

this will be a general tips section on what to do while playing around

the insides of your short block.

It

bears repeating, a healthy motor makes hp- a tired one will not.

If you

have the money and are using your car for pure racing 12.5 to 14:1 compression

seems to be the hot ticket. High-octane race gas of course is required.

For

street use, no more than 9.5:1 is recommended.

Aftermarket

pistons are readily available from TRW, Mopar Performance and J&E Pistons.

Stock

connecting rods are fine, replace the rod bolts with ARP units if

you're having the rods resized (shotpeening is not a bad idea either).

On

oil pressure, experts recommend 7 to 10 psi of oil pressure for every 1000

rpm of engine usage.

7 psi

+ 6000 rpm = 42 psi

10 psi

+ 6000 rpm = 60 psi

Also

make sure you're using Mobil One oil- a synthetic motor oil will make more

hp than a regular oil (frictional gains).

Speaking

of oil, a good baffled oil pan can help keep the oil in the pan where it

belongs. Without one, the crank whips the oil up and costs hp.

On

a 440 Mopar V8 this is good for 15hp at 6000 rpm!

Costs

range from $160 to $400 for a good oil pan.

2.5

liter owners can remove the balance shafts in the oil pan and pickup 10-14

hp for free- they are for secondary order vibrations and not needed.

I have done several turbo and non-turbo cars with no ill effects.

88-95

2.5 Dakotas don't even come with them, no room in the oil pan.

Just

drop the oil pan, remove the 6 bolts holding the balance shafts in, cut

the chain attached to the front of the crankshaft and remove it.

Plug the oil feed hole, which is located next to the number 1 main cap,

with a pipe plug (you will have to tap out the hole), reinstall the oil

pan and your done.

Another

bonus is less engine noise and a pan that holds another quart of oil.

A warning from Cliff...

On

the 2.5 86 to 88 motor swaps you need to install a distributor drive shaft

with a fuel pump

bump {out of your original

2.2} and when you install it you need to put it in 90 deg. out of

time... because the longer 2.5 rod hits the fuel pump bump. On my car I

moved the oil pump 90 deg also, so my distributor was correct but you could

just rotate the wires one hole also...

Of

course this only applies if you are running a carb and wish to use a stock

fuel pump. I would use an electric pump myself...

...note that the oil pump

hole is oval while the one at the surface of the block that it mates to

is round...

..take a die grinder and

make the one on the block match the one on the pump...

...Ed Peters swears there

is a 4 hp gain since pump does not sap as much power due to better oil

flow.....I tried it on my carb Horizon and MAYBE picked up .10...

...not really worth the

effort...

Unless

of course you have the motor apart and have a garage...

every

little bit helps..

Costs

range from $160 to $400 for a good oil pan.

2.5

liter owners can remove the balance shafts in the oil pan and pickup 10-14

hp for free- they are for secondary order vibrations and not needed.

I have done several turbo and non-turbo cars with no ill effects.

88-95

2.5 Dakotas don't even come with them, no room in the oil pan.

Just

drop the oil pan, remove the 6 bolts holding the balance shafts in, cut

the chain attached to the front of the crankshaft and remove it.

Plug the oil feed hole, which is located next to the number 1 main cap,

with a pipe plug (you will have to tap out the hole), reinstall the oil

pan and your done.

Another

bonus is less engine noise and a pan that holds another quart of oil.

A warning from Cliff...

On

the 2.5 86 to 88 motor swaps you need to install a distributor drive shaft

with a fuel pump

bump {out of your original

2.2} and when you install it you need to put it in 90 deg. out of

time... because the longer 2.5 rod hits the fuel pump bump. On my car I

moved the oil pump 90 deg also, so my distributor was correct but you could

just rotate the wires one hole also...

Of

course this only applies if you are running a carb and wish to use a stock

fuel pump. I would use an electric pump myself...

...note that the oil pump

hole is oval while the one at the surface of the block that it mates to

is round...

..take a die grinder and

make the one on the block match the one on the pump...

...Ed Peters swears there

is a 4 hp gain since pump does not sap as much power due to better oil

flow.....I tried it on my carb Horizon and MAYBE picked up .10...

...not really worth the

effort...

Unless

of course you have the motor apart and have a garage...

every

little bit helps..

Ignition

No

computers are available for the TBI cars. ND Performance is working

on this; a custom computer can be programed for your needs. (505)

458-6024

Computers are available from

Chrysler for carbureted applications.

P4529864 1978-1982

P4529865 ..........1983

P4529866 ..........1984

P4529867 1985-1987

The Mopar Performance

unit does have a good bit of ET improvement over the stock unit....compared

to the 110 HP Shelby unit it has less......in my case (110 hp) the MP unit

was worth initially .5 in

the 1/4 mile..but as air

temperatures rose, the improvement becomes less and less...

...starting out at 50 degrees

it was the 1/2 second improvement, but as the temps hit 80 it leveled off

to the same elapsed times

that I had with the stock unit.....on a non Shelby car the ET would still

be better.

Stock

spark plugs work excellent; RN12YC or for a colder plug, RN9YC.

.35

to .40 gap works just fine, do not go over .40

...I NEVER had luck

with Splitfires or Bosch

Platinums......nothing wrong

with stock Champions.

The

stock ignition coil works great as does the stock (mopar) spark plug wires.

If you

must use aftermarket plug wires get Magnacore wires or make a set

from Moroso spiral core.

Do

NOT use solid core wires! modern computers do not tolerate the

electronic

noise they generate!

No

computers are available for the TBI cars. ND Performance is working

on this; a custom computer can be programed for your needs. (505)

458-6024

Computers are available from

Chrysler for carbureted applications.

P4529864 1978-1982

P4529865 ..........1983

P4529866 ..........1984

P4529867 1985-1987

The Mopar Performance

unit does have a good bit of ET improvement over the stock unit....compared

to the 110 HP Shelby unit it has less......in my case (110 hp) the MP unit

was worth initially .5 in

the 1/4 mile..but as air

temperatures rose, the improvement becomes less and less...

...starting out at 50 degrees

it was the 1/2 second improvement, but as the temps hit 80 it leveled off

to the same elapsed times

that I had with the stock unit.....on a non Shelby car the ET would still

be better.

Stock

spark plugs work excellent; RN12YC or for a colder plug, RN9YC.

.35

to .40 gap works just fine, do not go over .40

...I NEVER had luck

with Splitfires or Bosch

Platinums......nothing wrong

with stock Champions.

The

stock ignition coil works great as does the stock (mopar) spark plug wires.

If you

must use aftermarket plug wires get Magnacore wires or make a set

from Moroso spiral core.

Do

NOT use solid core wires! modern computers do not tolerate the

electronic

noise they generate!

Fault

code charts for Carb and TBI

Carb and TBI

Vacuum

Diagrams for Carb and TBI

84 CARB 85

CARB 86 CARB

85 TBI 86

TBI 87 TBI 88

TBI

Fuel

System: Carb

Well,

the plus of running a carburetor is that you can adjust your

fuel curve to your liking.

The down side of course

is that you have to do it yourself!

plus, you lose the

smoothness of fuel injection.

GET

AN O2 GAUGE! ITS THE BEST WAY TO TUNE YOUR CARB!

I

have been using one on my 1970 GTX for over 7 years.

Carb

tuning and rejetting can be done in as little as an afternoon.

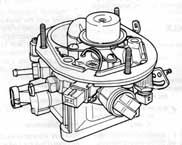

There are two basic 2.2

factory carburetors.

The Holley 6520 is a feedback

carb and the 5220 is not.

The 5220 flows a little

more air than the 6520. Caravans, Rampages and 87 2.2 Dakotas came

with the 5220.

The 5220 is also in the

Mopar Performance Catalog. PN: P4286772

I prefer the feedback carb

myself, due to the fact the computer can still adjust your fuel curve at

cruise for best gas mileage.

...the non feed back

carb flows more CFM (I have heard 100) but I do know that the non feed

back carb is better for

bracket racing and consistancy.....it has a power valve that can be

adjusted to open a bit sooner....on

the top of the carb is a tiny metal cap (1/4 dia) that can be

removed and under that is

a hex screw that is directly over the powervalve....simply turn the

screw in one full turn (per

Ed Peters)....or 1/2 turn (per me)......this makes the powervalve open

earlier.....for even better consistancy you would open the carb and plug

off where the

power valve is screwed in.....you

MUST richen up the secondary jetting when you do this.......

Jetting.....I run rather

lean for drag racing with a 225 primary and 335 secondary...

...for next year I will

go to a 355 secondary since I have now removed and pluged the powervalve......for

more power go richer yet.........hint....the old VW (1.7) powered L

bodies had huge secondary

jets in their carbs.....bigger than the jetting kit that is available from

Mopar Performance.

2.2

carb jetting package PN: P4286777

...at one time I put a Holley

500 cfm 2 barrel with mechanical secondary linkage on a 81 Horizon,

it ran absolutely no quicker,

and fuel mileage dropped a lot!!!

We used a 1 1/2" wooden

spacer to mate it to the intake...

Well,

the plus of running a carburetor is that you can adjust your

fuel curve to your liking.

The down side of course

is that you have to do it yourself!

plus, you lose the

smoothness of fuel injection.

GET

AN O2 GAUGE! ITS THE BEST WAY TO TUNE YOUR CARB!

I

have been using one on my 1970 GTX for over 7 years.

Carb

tuning and rejetting can be done in as little as an afternoon.

There are two basic 2.2

factory carburetors.

The Holley 6520 is a feedback

carb and the 5220 is not.

The 5220 flows a little

more air than the 6520. Caravans, Rampages and 87 2.2 Dakotas came

with the 5220.

The 5220 is also in the

Mopar Performance Catalog. PN: P4286772

I prefer the feedback carb

myself, due to the fact the computer can still adjust your fuel curve at

cruise for best gas mileage.

...the non feed back

carb flows more CFM (I have heard 100) but I do know that the non feed

back carb is better for

bracket racing and consistancy.....it has a power valve that can be

adjusted to open a bit sooner....on

the top of the carb is a tiny metal cap (1/4 dia) that can be

removed and under that is

a hex screw that is directly over the powervalve....simply turn the

screw in one full turn (per

Ed Peters)....or 1/2 turn (per me)......this makes the powervalve open

earlier.....for even better consistancy you would open the carb and plug

off where the

power valve is screwed in.....you

MUST richen up the secondary jetting when you do this.......

Jetting.....I run rather

lean for drag racing with a 225 primary and 335 secondary...

...for next year I will

go to a 355 secondary since I have now removed and pluged the powervalve......for

more power go richer yet.........hint....the old VW (1.7) powered L

bodies had huge secondary

jets in their carbs.....bigger than the jetting kit that is available from

Mopar Performance.

2.2

carb jetting package PN: P4286777

...at one time I put a Holley

500 cfm 2 barrel with mechanical secondary linkage on a 81 Horizon,

it ran absolutely no quicker,

and fuel mileage dropped a lot!!!

We used a 1 1/2" wooden

spacer to mate it to the intake...

Mopar Performance

has two carb packages.

One is the downdraft Weber,

which will bolt on your current intake mainifold

and makes good power over

your stocker. PN: P4349300

Note:

this may be a discontinued part number.

The other package is the

Weber sidedraft dual carb and intake kit which makes

max power with a carbureted

2.2/2.5. You will need the inake and two carbs.

PN: P4349086 and P4349087

x2

Mopar Performance recommends

2.5 to 3 psi of fuel pressure for the

Weber sidedraft carburetors.

..the dual 40 DCOE Weber

side draft carbs picked up my car from .75 to around a full second...

...you may need to relocate

the power steering pump for installation (my car was manual)...

..they have a problem with

heat soak from the header,

I suggest a heat shield

be fabricated and placed between the header and the carbs...

...these things have a real

neat sound when run with no air filters!!!

I

had the dual 40mm Webers and that will absolutely make you . . .

well . . . you know . .

when you turn the

key the first time. . .

Touch the throttle and you'll

need an underware change -- it will rev very freely and

quickly. This change

alone is good for about an easy 3/4+ second difference.

Be sure to use a fuel

pressure regulator on the dual 40mm Webers.

If

using the stock style carburetor take a 5/16 fuel filter and put it inline

with your charcoal canister. This will keep chunks of charcoal from

the

canister

out of your float bowl.

An electric

fuel pump will also help prevent vapor lock in hot weather. Chrysler

even had a pump package TSB to repair this problem.

Make

sure to remove the stock pump, block off the fuel pump hole in the block

and use a fuel pump regulator.

..the dual 40 DCOE Weber

side draft carbs picked up my car from .75 to around a full second...

...you may need to relocate

the power steering pump for installation (my car was manual)...

..they have a problem with

heat soak from the header,

I suggest a heat shield

be fabricated and placed between the header and the carbs...

...these things have a real

neat sound when run with no air filters!!!

I

had the dual 40mm Webers and that will absolutely make you . . .

well . . . you know . .

when you turn the

key the first time. . .

Touch the throttle and you'll

need an underware change -- it will rev very freely and

quickly. This change

alone is good for about an easy 3/4+ second difference.

Be sure to use a fuel

pressure regulator on the dual 40mm Webers.

If

using the stock style carburetor take a 5/16 fuel filter and put it inline

with your charcoal canister. This will keep chunks of charcoal from

the

canister

out of your float bowl.

An electric

fuel pump will also help prevent vapor lock in hot weather. Chrysler

even had a pump package TSB to repair this problem.

Make

sure to remove the stock pump, block off the fuel pump hole in the block

and use a fuel pump regulator.

Fuel

System: TBI

TBI

guys have it the hardest- there is very little you can do to fool around

with

your fuel system.

86-87

cars have the worst computers as they are very limited. They don't

have as much leeway as the 88 and up computers when it comes to injector

size and other parameters...

Here

are some tips and tricks...

Try

an injector from a larger engine (i.e. a 2.5 injector if you have a 2.2).

An adjustable

fuel pressure regulator or pinch valve.

(careful

they only run at 15 psi)

Plug

in a loose coolant sensor (when racing); the computer thinks the engine

is colder than it is, so it richens up the fuel curve.

ND Performance (505 458-6024) makes custom computers.

Call

him with your needs.

TBI

guys have it the hardest- there is very little you can do to fool around

with

your fuel system.

86-87

cars have the worst computers as they are very limited. They don't

have as much leeway as the 88 and up computers when it comes to injector

size and other parameters...

Here

are some tips and tricks...

Try

an injector from a larger engine (i.e. a 2.5 injector if you have a 2.2).

An adjustable

fuel pressure regulator or pinch valve.

(careful

they only run at 15 psi)

Plug

in a loose coolant sensor (when racing); the computer thinks the engine

is colder than it is, so it richens up the fuel curve.

ND Performance (505 458-6024) makes custom computers.

Call

him with your needs.

Fuel

System: Port Fuel Injection

This

here is the deal.

Momma

Mopar never made a PFI non turbo 2.2 in the USA.

They

did however make a 2.5 PFI called the Flexi-Fuel vehicle in 89 or 90.

It was

a spirit that would run on gas or methanol or any combo in between.

It was

used, if memory serves, in a government test fleet in limited numbers.

They

also made/make in mexico a PFI 2.2 combo.

Behold

the only 2.2 PFI non-turbo in the USA!

Got

bored one day seeing the Mighty K sitting with no motor in it.

took

a tbi engine that was hiding under a tarp and

slapped

an 89 2.2 turbo intake on it, welded up the egr tube and stuffed it in.

Runs

good but the spark curve is for a turbo car and it takes a dive at WOT.

I have

a custom computer on its way from ND Performance (505 458-6024) and I will

let ya know how it runs this winter.

You

know what they say,

idle

hands are the devils tools!

Got

bored one day seeing the Mighty K sitting with no motor in it.

took

a tbi engine that was hiding under a tarp and

slapped

an 89 2.2 turbo intake on it, welded up the egr tube and stuffed it in.

Runs

good but the spark curve is for a turbo car and it takes a dive at WOT.

I have

a custom computer on its way from ND Performance (505 458-6024) and I will

let ya know how it runs this winter.

You

know what they say,

idle

hands are the devils tools!

Tips

and Tricks

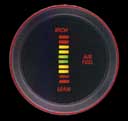

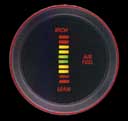

Get

a cyberdyne air/fuel gauge, it makes tuning a snap!

part

number 7009 - it's about $30 from summit racing..

it's

not just for turbos!

If you

have a carbureted car and can get away with it, lose the air pump...

..Couple

of horsepower hiding there.

Weight

is bad -100 lbs is equal to 10 hp or 1/10 sec in the quarter mile.

So you can lose weight or make more power- it's easier to lose weight and

parts last longer. Some examples:

get

a lighter battery (10 lbs), light weight seats (40-90 lbs), lightweight

wheels; empty your trunk-you would be suprised how much weight is lurking

in there; holesaw the bumpers behind the covers where it can't be seen;

pitch the a/c compressor. Hell, if you're desperate scrape the undercoating

off the car.

Now,

if you managed to pull 200 lbs from your car you just gained 20hp.

Simple

isn't it?

Get

a cyberdyne air/fuel gauge, it makes tuning a snap!

part

number 7009 - it's about $30 from summit racing..

it's

not just for turbos!

If you

have a carbureted car and can get away with it, lose the air pump...

..Couple

of horsepower hiding there.

Weight

is bad -100 lbs is equal to 10 hp or 1/10 sec in the quarter mile.

So you can lose weight or make more power- it's easier to lose weight and

parts last longer. Some examples:

get

a lighter battery (10 lbs), light weight seats (40-90 lbs), lightweight

wheels; empty your trunk-you would be suprised how much weight is lurking

in there; holesaw the bumpers behind the covers where it can't be seen;

pitch the a/c compressor. Hell, if you're desperate scrape the undercoating

off the car.

Now,

if you managed to pull 200 lbs from your car you just gained 20hp.

Simple

isn't it?

REPEAT

AFTER ME - THERE IS NO REPLACEMENT FOR DISPLACEMENT

Drop in an 89-up 2.5 in a carbureted car and enjoy the extra ponies.

Just

swap over the intake to a carb model and away you go.

And

remember to pull the balance shafts before installing the engine.

This

can also be done with a TBI car as long as the computer is swapped with

the engine and fuel injector.

86-88

2.5's had a taller deck height so they might be a tighter fit in smaller

cars; plus the exhaust sits up 11mm higher.

Install

a manual transmission if you can and have the tech know how; there are

less hp losses with a manual and you have 2 extra gears to work your powerband

PLUS your gas

mileage goes up as well as the top speed of the car.

Install

a turbo clutch and flywheel; it has a 15mm larger disk and you may never

have to change a clutch again.

A

tip to carb owners using the stock air cleaner setup. Mopar Performance

says to stack 3 gaskets at the air cleaner to carb junction for better

air flow.

Absolute

quickest and cheapest ET gains on these cars, get rid of the air filter

assembly.

Run a ram air hose to the

carb, but make sure you use some sort of fine wire mesh

air filtration. I made a

very tiny screen frame that fit inside the stock air filter assembly, then

plugged all openings to

the air filter box except where the air hose comes from the

computer. That is where

I hooked up the ram air...very easy to do..

Drop

in a 185 degree thermostat for more power, cooler running and better detonation

resistance.

Do not

install a 160 thermostat- excessive wear of the rings will result.

Short

on cash? - get a turbo exhaust system from a junk car of the same model.

Cut the flange off up front, weld on your tbi/carb exhaust flange and it's

a bolt on.

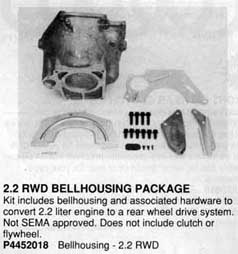

For

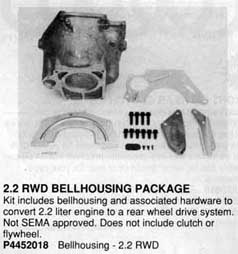

those of you considering a RWD conversion...

Mopar

Performance used to have a 2.2/2.5 bellhousing kit in the catalog.

It was

just stock Dakota parts that were bundled in a package.

For

those of you considering a RWD conversion...

Mopar

Performance used to have a 2.2/2.5 bellhousing kit in the catalog.

It was

just stock Dakota parts that were bundled in a package.

Spending

Money

Well,

you can get an underdrive pulley which is good for 10-11hp for $75.

K&N

air cleaners are mandatory equipment. they are cheap and good for

a 1-2% horsepower increase.

you

may never have to replace an air filter again.

Another

good choice would be a nitrous oxide kit, 50 hp at the touch of a button.

Only problem is when the bottle runs out; but 50hp of juice lasts

a long time.

The

carb part number from NOS systems is: 05011

The

TBI part number is: 05118

note:

I do not know if this is for 84-85 E.F.I.

or 86-92.

you

may never have to replace an air filter again.

Another

good choice would be a nitrous oxide kit, 50 hp at the touch of a button.

Only problem is when the bottle runs out; but 50hp of juice lasts

a long time.

The

carb part number from NOS systems is: 05011

The

TBI part number is: 05118

note:

I do not know if this is for 84-85 E.F.I.

or 86-92.

714-546-0592

ICE

Nitrous systems used to have a nice kit for the Carb 2.2, but I think

they

are

no longer in business.

714-546-0592

ICE

Nitrous systems used to have a nice kit for the Carb 2.2, but I think

they

are

no longer in business.

The

part number was: 30023

1-800-845-2383

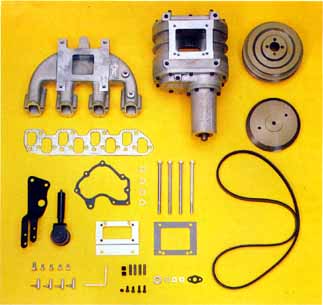

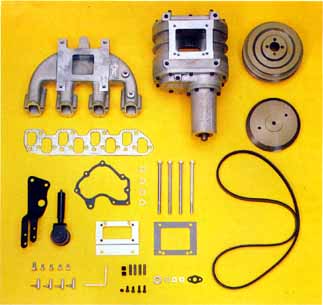

Mopar Performance used

to list a supercharger for the 2.2 engine (P4349478)

Development work was done

at the Carol Shelby Performance center,

and it was manufactured by

B&M for Chrysler. It was also listed in the B&M catalog,

part number 90601

The

part number was: 30023

1-800-845-2383

Mopar Performance used

to list a supercharger for the 2.2 engine (P4349478)

Development work was done

at the Carol Shelby Performance center,

and it was manufactured by

B&M for Chrysler. It was also listed in the B&M catalog,

part number 90601

Dealer cost on this in 1987

was $1400!

It made with the stock carb

130hp@5200 RPM.

With the Weber carb (PN P4349300)

the hp jumped to 155@5200 RPM.

Dealer cost on this in 1987

was $1400!

It made with the stock carb

130hp@5200 RPM.

With the Weber carb (PN P4349300)

the hp jumped to 155@5200 RPM.

Links

Angleo

Taylor

Bradley

Miller

Tom

Byrne

Thanks for stopping in!