Common failures and mistakes

1) Loose motor mounts.

The front mount is the most common with the passenger side coming in second (The transmission mount is rarely ever a problem) When the front one loosens up (usually the two bolts going into the transmission bellhousing) it allows the mount to rock back and forth breaking it and sometimes wiping out part of the bellhousing as well. When the passenger side mount is allowed to get loose (the large fastener on the underside) it lets the motor sag throwing off the axle geometry and guess what? You starting having axles fall apart! Get out a big breaker bar and tighten those bolts!!

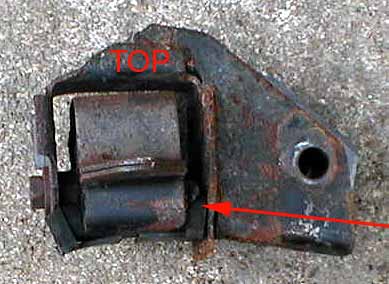

2) Incorrectly installed motor mounts.

How can people screw this up? Take out the mount, look at how it came out and put the new one in.... But no...

See the arrow? That's the direction the motor tries to rotate under acceleration. The two red lines in the lower mount show how the correctly installed insert will spread the load from the center bolt downward through the rubber to the outside of the mount. See the top mounts insert? Some yahoo installed it 90 degrees off- When the engine torque's up not only will it vibrate like crazy because the center post will push directly to the outside of the mount, it will also stress the hell out of the CV joints because the engine is moving farther then it should.

Mount mistake number two- The passenger side mount is directional as well. See the arrow? The insert has been installed upside down. Engine is now cocked way up in the air AND vibrating like crazy. Just great for the axles. Also there was 2 1/4 thick washers under the mount when you took it off- put them back. Chrysler figured out that they could minimize torque steer by having them there... And while your poking around your motor mounts, check the drivers side.. they break from time to time, the engine sags and vibrates like hell too.

3) Grounds.

Everyone misses the grounds and it's the most critical aspect of your car's electrical system. The number one ground that causes the most problems is the one that attaches to the intake manifold at the fuel injector harness. It's that big eyelet that the passenger side bolt of the fuel rail runs through- people pull the rail to change injectors and reinstall the rail and miss the ground! The relays go batshit when the key is turned on, the computer won't give codes, etc. etc. Worse is when the eyelet is resting on something metal making a ground contact and when you drive off the engine rocks- It looses connection, the car dies, the engine rocks back, it makes connection again, the engine fires back up, the engine rocks back again, it dies. you get the picture.

4) '86-94 distributor falling apart.

Chrysler when to some funky plastic mounted distributor shutter wheel in '86 and it's been nothing but trouble since. The problem is when the unit gets high miles on it the melted plastic "blobs" that hold the wheel in place start to loosen up and the shutter wheels starts to wiggle around.

No big deal right? Guess what looks at that shutter wheel- the ECU. What's the ECU doing looking at that for? It's how it tells where Top Dead Center is and bases firing the injectors, coil and knock retard information from. Typical symptoms it's dancing around is rough idle and surging driving down the street. So pop off those distributor caps, rotors and pick-ups and peek down there and make sure it's A-OK.

5) Distributor pickup.

Some people have these things go like popcorn, I have been lucky I guess and never had a failure. Still I keep a spare in the glovebox with a Phillips screwdriver just because.

6) Spark plug wires.

While we are on the subject of distributors one VERY common mistake is to not insert the plug wire fully into the distributor cap. Pull back the boot and push in the end till you hear a distinct "click" and you can see that the terminal is fully seated in the cap.

7) Jumped timing belts.

This is so common it should be in the owners manual under troubleshooting. I get dozens of e-mails from people asking why their car doesn't run right and this is problem numero uno. The problem is these engines can skip a tooth and still run well- turbochargers cover a number of sins. A good backfire can jump the belt or 9 times out of ten it's a shield that's been left off the side of the engine letting in a piece of road debris in the belt area. So make sure that you have both upper and lower covers (and they don't have pieces broke off), the adjusting tool access hole has it's plug in it, the chunk of foam is in the pass/side motor mount cavity (only early years I think) AND the engine cover is still installed on the body below the crankshaft pulley. Of course it helps if the timing belt is tensioned correctly too. Don't ASSUME because the distributor timing is on the cam timing is correct- I have seen one or the other be off. Check out this page to see if yours is correct.

8) Distributor timing procedure not followed.

Seen this more then a few times- The Coolant Sensor Must Be Unplugged! It's the sensor to the right of the thermostat right in front of number four sparkplug.

A) Start car, run till normal temp.

B) Unplug coolant sensor, cooling fan WILL turn on.

C) Set timing to 12 degrees, lock down distributor.

D) Shut car off, plug sensor back in- On 84-87 vehicles disconnect battery to

reset computer.

Simple no? If your mechanic cannot follow this procedure, find another one or do it yourself.

9) Wrong rear cam seal.

This one I don't run into very much anymore but it use to be more common... The 80-86 engines had a seal on the back of the cylinder head instead of the cap that's used on the 87+ EFI motors... what most people don't know is that's it's a reverse rotation seal that's designed to push oil away from the outside edge of the seal. So what happens is that people install a normal seal here (which has the direction grooves for clockwise rotation) and oil is forced OUT the seal. So make sure you have the right seal OR replace the seal with the later model cap if your not running an air pump.

10) Rear cam plug falling out.

Well it's not so much falling out as loosing tension with age and blowby from a high mileage engine pushes it out. Next thing you know there is a cloud of oil behind you and several people have managed to drive their car long enough to loose all the oil in the engine and damage the motor! To prevent this from happening (or while re-installing) put a thin coat of Permatex Number 1 (Which is NOT RTV) around the seals perimeter and push it back in. You can use RTV but I don't recommend it. Permatex Number 1 doesn't quite dry and stays flexible so it grips the head better compared to RTV which while drying is a hell of a lubricant and when it does dry the engine oil slowly starts to seep it's way around it.

11) Wrong year waterpump.

Chrysler more or less used the same

clockwise turning waterpump from 1980-1988 for the 2.2 engines. In 1989 with the

introduction of the common block engines however they did a tricky- Counter

rotating water pump that was driven off the BACKSIDE of the alternator

belt. Guess what happens when you install a early belt setup on a later

engine? It overheats.

Happens all the time too... how to tell which waterpump you have? The

early pump is sealed to it's housing with RTV, the later with a big rubber

o-ring. The early waterpump pulley has 5 ridges on it, the later is perfectly

smooth (runs off the back of the belt remember?)

12) Cylinder head snafu's.

Chrysler made a number of changes based on usage and years- One common mistake is to install a TBI or carburated car head on a turbo engine, this will work but the valves and springs are not rated for turbo use and sure as death & taxes the engine will burn an exhaust valve within a year. Another snafu is that the '86-93 heads use a 2 mm longer valve then the pre-'86 heads. Install a later model valve in an early head and guess what? The valve won't close!

13) OSJ cylinder head.

Ever see a cylinder head stamped "OSJ" where the cam comes out the back of the head? It means Over Sized Journal and takes a special factory camshaft! What happen was once in a while during machining of the head casting the machine would go to far while boring the hole for the camshaft. So instead of tossing the expensive casting out Chrysler just ran off a bunch oversize cams to fit them. Needless to say there are no aftermarket cams available for this head. Oh and if your tempted to install a regular sized journal cam you will find that your lifter will be collapsed because all the heads oil pressure is lost out the cam journals.

14) Mixing turbo distributors.

Seen this before- People trying to use a 86-93 distributor with a 84-85 electronics or vise versa. Car won't start or run very poorly, Chrysler did this for a reason because of the very different spark advances between the pre-86 engines and the early motors. 84-85 Logic Modules MUST use 84-85 distributors and 86-93 ECU's MUST use 86-93 distributors.

15) Valve cover gaskets.

Do NOT use the cork inserts (84-88) that come with some valve cover kits (NAPA) Use just the rubber end pieces and RTV like Chrysler intended and you will have no problems. While were on the subject Fel-pro makes a blue "perma dry" rubber seal for the 89-93 engines- it sucks. Get the black valve cover seal from Chrysler to prevent problems.

16) Torque specs snafu's.

I have seen people try and torque 10 mm headbolts to 11 mm spec AND use 10 mm headbolts in 11 mm block, check your production dates when in doubt.

SOHC 1980-1985 use 10 mm headbolts that

are torqued to 35-45-45- 1/4 turn

SOHC 1986-1993 use 11 mm headbolts that are torqued to 45-65-65- 1/4 turn

17) Wrong transmission.

Seen a bunch of turbo car's with wrong manual or automatic transmission because some junkyard down the line sold then current owner or garage a tranny while using the phrase "It will bolt right in, their all the same."

They are not.

EFI and carburated transmissions lack the heavy duty internals the turbocar transmissions came with, so look before you buy. The manual transmissions aren't that bad but some of the auto's burn up pretty quick.

18) Rear engine & turbocharger support brackets.

People are always leaving these things off- Don't they realize that the rear engine support bracket is a major support that prevents the block and transmission from becoming damaged? The turbo bracket is there because Chrysler had problems with manifold & turbo housing cracking during durability testing... So do yourself a favor- Put The Brackets Back.

19) Oil feed line to turbocharger

Changing headgasket or turbo and have the head off? Replace this line. I have seen them go and then the car burns.

20) Cruise control not working after computer swap

88-93 Chryslers use the ECU to control the cruise control - Guess what though? Not all ECU's have the circuits to run the cruise control! Scenario is you computer dies and you run to the boneyard and grab one, install it and everything is well except that the cruise doesn't work. Surprise! You got an ECU from a non-cruise control car. Boned!

21) Cracked flexplate

Weird noises in the bellhousing area? Could be loose bellhousing bolts (which are a dead ringer for rod knock) or the dreaded cracked flexplate. If your going to have the transmission out for any reason replace this part! See the flexplate above? The center is totally cracked out!

22) Logic Module covering bag.

The LM on most cars has a bag over the wiring to keep water out. You would be suprised on how many cars don't have this anymore and their owners get very suprised when they get a good rain and the car stops running! Worse case scenario is it shorts the unit out which I have seen happen.