Dyno day 1/25/03

On 1/25/03 R.P. rented out the Dynojet at Gary Wang's Auto Sales to do some research, baseline a few cars and refine calibrations. Six cars went up but only five were tested & tuned due to time restraints.

We will have to find out how well the Reliant runs next time ;-)

Butch and Cliff's rides waiting for their turn.

Here are the results and conclusions...

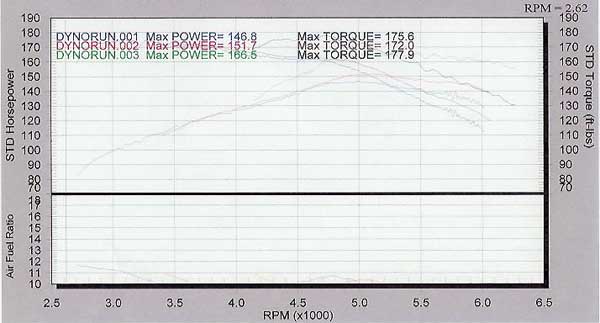

First up was Butch Nordstrom with a recently acquired 1992 IROC Daytona 2.2 16V. The car was bone stock except for the addition of a Grainger valve for boost control.

Unimpressive to say the least! Butch's car seemed to be having a number of issues- The a/f ratio was almost off the chart it was running so rich and the muffler out back was making the most pitiful sound you could imagine. A close look showed that it was some generic factory replacement muffler which are notorious for "being one size fits all"

So Gary Wang provide us with a saw and we gleefully whacked it off.

Looking a little better! Car picked up about 15 hp and 40 ft/lbs of torque. Still lower from factory spec but we suspect due to the overnight cold soak the dyno was reading low (increases the friction in the dyno's roller bearings for the drums) and Butch's car might have the cam timing off as well. Baseline done we move onto the next car...

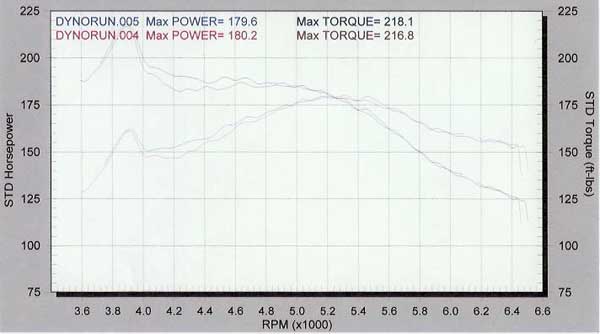

Next up was my 89 Daytona which is being used for a baseline calibration for 3bar SMEC and 52 pph injectors. The car has a stock swirl head, stock intercooler and stock turbo with 3 inch exhaust.

Still driving it year round!

On the early runs it was easy to see that the calibration was far to rich as the fuel ratio would drop right off the scale (the necessity of checking the calibration on the dyno with wide-band feedback was painfully clear) The car ran fine on the street but the dyno told a different story. 14 pulls later (with the boost locked at 20 psi on pump gas) and the spark & fuel tables were optimized with a nice flat a/f ratio.

Run 15 was a 25 psi blast with a some octane booster added for insurance as by now the intercooler was quite warm!

Again it's noted that the dyno numbers are low- The car was baselined line last May and made 15 more hp and 20 more ft/lb of torque even though the spark timing at 20 psi remains the same and the a/f ratio is far more consistent across the board. This is why it's important to use a dyno as a tuning tool to find out what changes increase peak hp and torque during the session your are working in.

Drivetrain configuration- Bone stock '89 engine & stock intercooler with the exception of a ported exhaust manifold, backcut valves, cone filter and three inch exhaust system with Hooker Max Flow muffler & A-568 5 speed transaxle.

All fueling is handled by RP SMEC with 52 pph injectors and 3 bar map sensor with base fuel pressure at 55 psi.

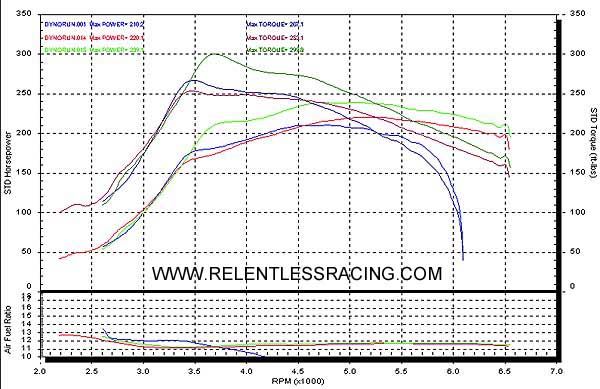

Next up was Jon Genesky's 88 CSX-T- The primary difference between Jon's car and mine is that Jon's car is equipped with a "G" casting cylinder head (with appropriate spark curve) and S60 turbo.

After several pulls to get the fuel & pumping tables where they should be it was interesting to note some differences and similarities between Jon's CSX and the Daytona. Between the larger turbo and G casting head Jon's car could not beat the Daytona's torque figures, you can clearly see that ramp up in torque. What was interesting to note that even though Jon had a better flowing head and turbo that both cars had identical fuel and pumping tables over 4000 RPM!

This is caused by running the factory intercoolers at 20 psi of boost- They are having a regulating effect on airflow in the upper rpm bands of the engines operation. Had Jon's car had a better intercooler his G-head and larger turbo would have really shined and made more peak hp then the Daytona.

Altering the cam timing had no effect on pushing the hp peak up, again we are running into a masking effect by the intercooler at the boost levels the engine was run at. Things would be different if the cars were run at 12 psi where the cooler would be less of a restriction!

Jon's last pull of the day was interrupted by his 520 transaxle coming apart in 3rd gear! The hp & torque of the engine was to much for the unprotected 520 gearset. Jon had not installed a chrome-moly plate to help prevent the problem of 3rd gear deflection. The transaxle is getting repaired and will be back to the dyno soon.

Perhaps our slogan should be "we break parts so you don't have to!"

Drivetrain configuration- '88 .020 over shortblock with 85 rods, 85 G-casting cylinder head, 88 roller cam with RP adjustable cam sprocket. Ported exhaust manifold, S60 turbocharger with 2.25" outlet, cone filter and three inch exhaust system exiting out the side with Edelbrock RPM series muffler & A-520 5-speed transaxle.

All fueling is handled by RP SMEC with 52 pph injectors and 3 bar map sensor with base fuel pressure at 55 psi.

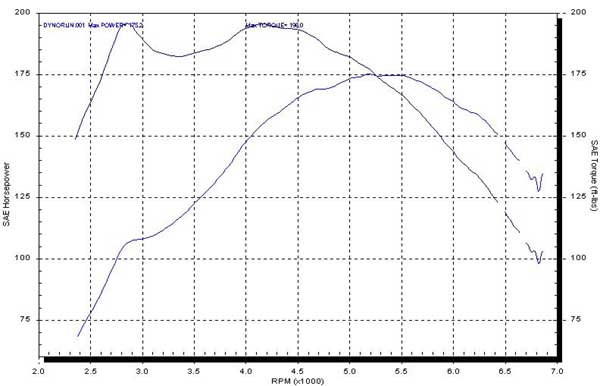

Next up was Cliff's 2.5 16V Reliant wagon- With only a few hundred miles on the clock Cliff just wanted to make 2 low boost pulls to get an idea how much hp he was making.

Right before the install.

175 hp and almost 200 ft/lbs of torque.

Drivetrain configuration- TIII engine with 2.5 pistons and crankshaft, RP adjustable cam sprockets, hybrid turbocharger, NPR intercooler and large free flowing exhaust & A-568 manual transaxle.

Last up was Brian Slowe's 11 second 2.5 16V Shadow- I had hoped to get the Reliant on the dyno but we were rapidly running out of time so Brian's car would be the last.

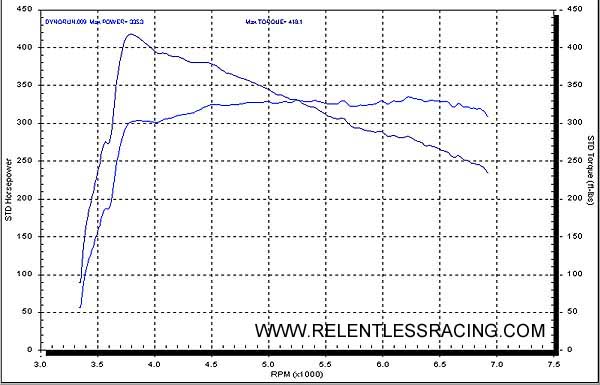

Several pulls were made with the car breaking up till the factory coil was replaced- Brian is right at the edge what you can do with a conventional ignition! Luck would have it I had a spare Blaster III coil in the van for the Reliant and we were able to get the car running well enough so the fuel tables could be adjusted and lay down some good pulls. The first clean run was number nine and the Shadow rapped off 335 hp and 413 ft/lbs of torque at 16 psi of boost.

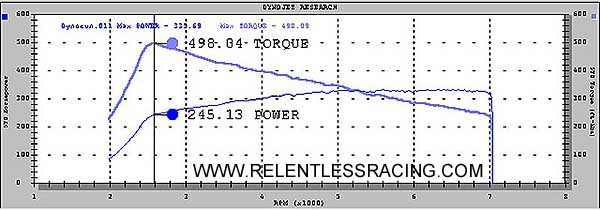

The most impressive run was number 11- The engine made peak torque at such a low RPM the Dynojet software would not even display it! We downloaded the data files and used Dynojets's downloadable home viewer which displays readings below 3000 rpm. You can see Brian's car kicking out a massive 498 ft/lbs of torque at 2600 rpm all at 16 psi!!

The datafile can be downloaded here and the viewer can be downloaded from www.dynojet.com

We upped the boost to 20 psi since it was clear the fuel curve for the 75 pph injectors was spot on but were greeted by the familiar sound of spark plugs being snuffed out. Brian is currently upgrading his car to a capacitive discharge system similar to what is currently used on the Reliant.

Drivetrain configuration- TIII engine with 2.5 pistons and crankshaft, DOHC 2.0 Neon cylinder head with RP adjustable cam sprockets, Stratus exhaust manifold, custom intake manifold with 58 mm throttle body, RP hybrid turbocharger, triple core intercooler and large free flowing exhaust with A-413 transaxle.

All fueling is handled by RP SMEC with 75 pph injectors and 3 bar map sensor with base fuel pressure at 55 psi.