Dave St.Louis 11 second 1988 Dodge Shadow ES 2.2 16V

Dave's super clean car is at home on the street, strip or show!

Some background history from Dave-

I bought the car (1988 Shadow ES) in Oct. 93 for $3500 with 150,000klms on it. It came with the non-intercooled 2.2 4cyl. When I bought the car I didn't imagine going this far with it but I read about some of the stuff that MP had brought out called "Super 60".With bolt on parts 300hp was available. I had gradually planned to buy all these parts (computer, turbo, injectors, cam, head, intake) and build a fresh motor. As I drove the car everyday, I began to tweak it a bit and found out that you could make a very noticeable difference in power by small changes. First things were a K&N filter, no cat. converter, and a homemade adjustable bleed for more boost (12psi) above the factory 7-8 psi. This was good for low 15s in the 1/4. I then converted to intercooled with a used intercooler, computer, injectors, and turbo out of an 88 (turbo 2) Daytona. I added the air charge temp. sensor wiring which the T1 cars did not have. I also put on a fresh home pocket ported head at this time, and a 52mm throttle body off a 95 3.3V6 minivan. This was good for low 14s in the summer of 1996 on street tires. I then eliminated the aircleaner housing in favor of a big K&N, installed a homemade 3" exhaust system to the factory 2 1/2 downpipe and increased boost to 18psi. To do this I had to put a zener diode on the factory computer to "fool" it into thinking it was only getting 14 psi as it has a fuel cutoff to prevent any higher. On slicks this was good for 13.20s at 104 mph in the fall of 1997. I then installed a Spearco intercooler in the front of the rad with custom homemade piping, 20% bigger MP injectors, adjustable fuel pressure reg (to be able to turn the pressure down at idle to work with the bigger injectors), a rising rate of gain regulator to add more fuel pressure under boost and relocated the K&N in front of the rad. I also relocated the battery into the right front bumper to help with traction which is still bad even with slicks to this day. With the wastegate not opening at all and the turbo delivering all the boost it can, 20psi, the best ET has been 12.89 at 107 with a 1.98 60ft. The car also sees time on road courses from time to time so has some suspension and brake mods. The car is very reliable, is drove to the track and back and now has over 215,000 klms with out the stock shortblock ever being apart. Only breakage has been one axle shaft twisted in half.

Since then? Well... Dave's been busy.

DOHC Turbo intercooled power- DONE RIGHT.

Short block is all basic stock T3, no balance shafts, rods have been ground on the sides and shotpeened, ARP rod bolts and main bolts.

Pistons are stock and have been ceramic coated on the top (this seems to have helped with the coolant and oil temps as this runs cooler than the old T2 I had in the car) and moly coated on the skirts. It was all balanced. Stock T2 rings with Neon (3mm as opposed to 4mm) oil ring expanders. Block was a low mileage one that I just ran a ball hone down the bores to clean it up. Has used zero oil so far and even with all the flogging at SDAC 10 it hasn't even got the crankcase vent damp with oil yet!! So I guess the shortblock sealed up good.

Oil pan I made myself, its a 2.5 pan with all the sound deadening taken out and a flat baffle around the sides and back. Then on top of that there is a windage screen, that is bolted to the pan that sits about 1/2-1/4 from the crank. All assembly of engine done by me. Intake is ported by me, and has an opened up entry and a 58mm TB (99 3.8 minivan) and the ports by the injector bosses have been opened up quite a bit. Exhaust manifold has been fairly well opened up too. No extrude hone etc . Fuel rail is stock other than the holes have been opened up a bit that supplies the injectors. Head is a stock slightly used one at this point as I had trouble with a ported one I had. It was also o-ringed but due to using the stock head for now, its not. Stock head gaskets and bolts. I also had custom titanium retainers (Trick Titanium, Detroit 248-588-9430) made which raise the installed height of the valve spring .100 thou as the spring pressure is too high in my opinion. Cams, valves, springs etc are all stock stuff. Has a oil cooler off a 98 3.8 minivan.

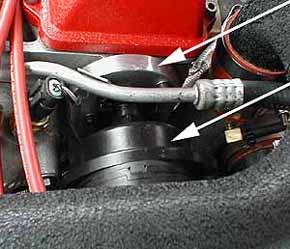

I also use a distributor on the exhaust cam. I used an oval 1/2 thick piece of aluminum, a stock distributor that I re-indexed the reluctor on, and a stock pickup coil. I did this so that if need be and I get stuck somewhere, its easy to get parts, plus its cheap! I tacked an oil slinger at the stock drive cog on the distributor and so far no oil leaks, as there is no seal on the shaft. Timing is set at 12deg. Computer for now is a 89MP T2 one with one of my zeners. Shift points are about 6400-6500, right at the edge of the rev limiter. I have another custom cal. computer in the works, that hopefully will work alot better. I REALLY need to get the revs up some, its REALLY starts to pull hard a 4500 or so.

Injectors are S60 ones (52 pph) and I run about 33PSI at idle and under boost the rising rate one so far bumps it up to about 80 psi at about 20 psi boost. Has the 255lph Walbro pump in the tank.. Still using the front mount Spearco intercooler, part #2-221-A. I use a Paxton regulator for 1-1 pressure and a Cartech for rising rate.

Trans is a 568 with a Quaiff diff. Clutch is a Revlock 2 from Mcleod, and an aluminum flywheel. So far works very well and holds good but DOES chatter a bit pulling away in first gear. Axles are unequal length GKN stock ones, no breakage so far. Turbo is a Turbonetics T3/T4 hybrid (no ball bearings) its a Stage 3(TA34) turbine wheel in a .63 A/R housing and a TO4E .50A/R compressor housing with a 57 trim wheel.

Wastegate is a Deltagate that is hooked to a custom 3in downpipe, with a stainless flexjoint I made up. Spoolup is EXCELLENT. I'm glad I didn't get the ball bearing option. I use a Grainger for Darren Dawes to regulate it. One very strange thing about this motor is how detonation resistant this thing is. Even at 18psi on 94 pump gas it doesn't show any sign of detonation in the knock table on a scanner. The only thing I can think of is that maybe the turbo being such low restriction on the exhaust side really helps with this. On the other motor any more than 18 psi would light up the knock table. I also have a test port on the turbine housing so I can keep an eye and see what the exhaust pressure in the manifold gets up to.

I saw Dave's car at SDAC 10 (where do you think a few of these picture came from?) and it was a masterpiece of workmanship. Dave has built one sweet machine.