N/A EFI cylinder heads & camshaft

Cylinder heads-

The first

cylinder head used with a TBI application was the "bathtub" chamber

head from 1984-1985. The second head is the "swirl" chamber or

"fastburn" head used from 1986-1995, It has a 6 cc smaller chamber.

|

1983-1984 2.2l |

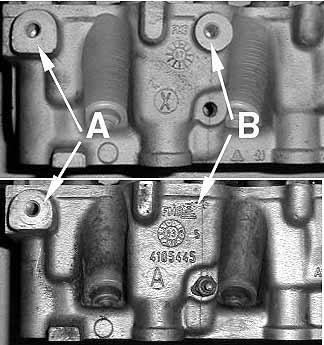

Casting number 4105445 |

|

1985 2.2l |

Casting number 4323287 |

|

1986 2.2l fastburn |

Casting number 4105782 |

|

1986-1994 2.5l TBI |

Casting number 4105782 |

Valve springs, keepers, retainers and lifters were all interchangeable

from 1984-1995 between the TBI applications.

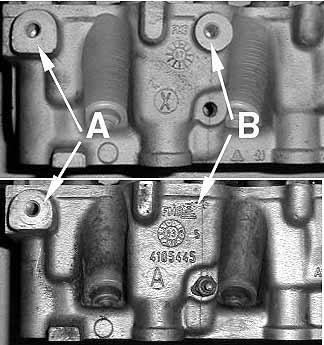

Here

is another physical difference between different year cylinder heads. The lower

head shows the typical A/C mounting boss used from 1981-1984 while the later

model upper head has an extra boss in location B. You can use the early

head on a later model car, just one of the bosses won't be there for the

a/c bracket...

IMPORTANT CYLINDER HEAD CHANGES TO BE AWARE OF!

1) SWIRL PORT HEAD VALVES ARE TALLER THEN BATHTUB HEAD VALVES, DON'T MIX THEM!

Overall height of a 86-65 SWIRL head valve is 114 mm, 82-85 BATHTUB head valves are about 112 mm. Using a swirl head valve in a bathtub head will cause the the valves to stay open causing no compression.

2) Oversize journal cylinder heads

Mopar had a few screw ups in machining cylinder head cam journals. Rather then throw out these heads, they machined them out to an oversize journal size that requires a special oversize journal cam. Needless to say there are no performance cams available for these heads and you should avoid any head stamped "OSJ" on the drivers end of the head. Using a stock cam on this head will cause a massive loss in oil pressure!!! First indication that you have installed the wrong cam in the head will be the refusal of the lifters to pump up due to the massive internal oil pressure leakage..

3) Discontinuation of cam lobe lubricators in 89-90

Chrysler used slider cams in the 2.2 & 2.5 engines till 1988 when they started phasing in the roller cam shafts. For cam lobe lubrication purposes the cylinder head cam tower caps were machined for "oil squirters." These would shoot a splash of oil onto the cam lobe when an oiling slot machined into the cam journal lined up with the oil passage lubricating the journal and a channel in the cam tower. Early 88 roller cams still had the "lube slot" cut into them and was done away with by 1989. The roller cams needed much less lubrication then the slider cams! In late 1989 it appears Chrysler did away with the oil squirt passages on cam caps 2, 3 & 4 altogether! A slider cam on one of these cylinder heads would rapidly wear out I would imagine. Please inspect your 89+ casting before attempting to install a slider camshaft!

84-88 cap on left, 89-95 on right

You maybe able to have the

caps machined for the oil squirters, swapping caps from an early head really

isn't a viable option due to the fact the head would have to be re-machined for

the new caps.

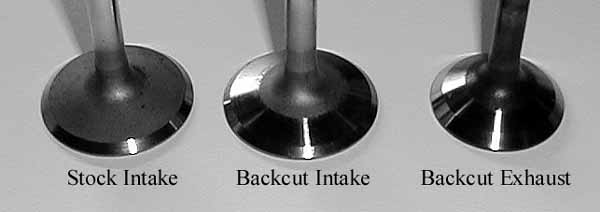

One

little trick I have done to my Daytona was to have the valves backcut. This

involves have material removed off the back of the valve head and improves the

flow over and around the valve. The "magic" numbers for the cuts are

20-21 degrees for the intake valve, 31-32 degrees for the exhaust valves (which

number you use will depend on your valves face cut)

Porting and polishing of cylinder heads is best done by a professional with

access to a flowbench. Unless you have lots of practice and have done

several, it's very easy to damage a head and make it unusable. I don't have any

further information on how well an EFI N/A would respond to a ported head, I

suspect the gain would not be that great due to intake manifold issues. Change

out the intake however and I think some real gains could be find here.

Headgaskets

Without a

doubt the best headgasket money can buy for a 2.2 is the factory gasket from

Mopar, here is a list of the following part numbers from the MP Catalog.

|

P4452005 |

Carb and Turbo I |

|

P4452006 |

Turbo II & 2.5 Turbo I |

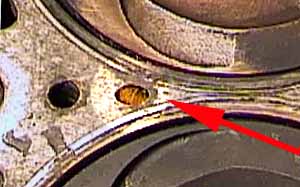

NOTE- The later TBI (91-95) engines come with a crossed drilled cylinder head like their turbo counterparts and it a good idea to use the cross drilled TII headgasket.

The best way to check is when you pull the head off the car look at the block and see if it has small angled hole in the indicated area. If it does, it's cross drilled! Order a SOHC turbo headgasket, 1989-1991 vintage.

My opinion of Fel-Pro 2.2 headgaskets? THEY SUCK. I have seen them fail in as little as 3000 miles on a 2.2. When it comes to V8 engines Fel-Pro is the brand I reach for (they are on my GTX as a matter of fact) when it comes to 2.2 liters, reach for Mopar Performance.

Fel-Pro does make a nice copper shim marketed as a "engine saver shim" for our engines if you are looking to drop your compression a bit if you have had to much milled off. NAPA also sells a engine saver shim (non cross drilled engines only) part number is 3688S - manufactured by Dana Victor.

Speaking of milling, .20-.30 milled off your head is equal to 2 degrees of retarded cam timing. Get offset cam keys or an adjustable cam sprocket to set it back (unless you want your cam timing retarded of course)

Need

headbolts? Go Mopar as well, they cost less then Napa's or Fel-Pro's and work

much better. 1983-1985 use 10mm headbolts and are torqued (in ft/lbs)

35-45-45-1/4 turn and 1986-1994 are 11mm and are torqued 45-65-65-1/4 turn.

Camshafts-

The SOHC engines were equipped with slider camshafts from 1984-1987, 1988 was a transition year with the 2.5 getting a roller in the beginning and the 2.2 receiving the roller later on. Slider cams can be installed in later engines and roller cams can be installed earlier engines. Why would you want to install a roller cam? They almost never wear out and are virtually silent in operation. There isn't much difference in performance with the milder roller cam because there is so much less friction. Don't attempt to use a Turbo camshaft for a N/A application- it has MUCH less duration then a N/A cam and you will lose performance.

As long as you keep slider rockers with slider cams and roller rockers with roller cams you wont get into to much trouble. If you are planning to use a slider cam in a late model head make sure you check for the lubrication squirters in the cam towers. If they are not present premature wear of the camshaft will occur!

There are a number of camshafts on the market for the SOHC N/A engine, unfortunately I don't have much information on them! Mopar Performance lists four that should give the factory computer little or no problems, and there are several other manufactures that sell them as well. The factory valve springs are good for approximately a .460 lift cam, I wouldn't want to good much over that unless you were going to change them out. In general cam swaps have little effect on the N/A EFI engines because the intake manifold is so poor. Some engineers at Chrysler did some cam swapping on a EFI motor that was on the dyno and that was their conclusion.

Derek Beland tried out a Comp Cams slider in his 92 2.5 Daytona and this is what he had to say-

I installed a Comp-Cams High-Energy cam (22-127-4), which is one step above stock; I believe the lift was .430". The effect it had on the car's drivability was subtle, but useful. With the stock cam there was a sweet spot in the middle of third at around 4800 RPM where the car made the most power. The new cam seems to have spread that out up and down the whole range. I can't really say it made that many more ponies at the top end, didn't feel like it anyway. I had to advance the timing to about 15 degrees to work well with the cam. One of these days when I have some free time I may experiment a bit with the initial advance to see what it likes best. It also hasn't been degreed properly, so there may be more ponies lurking under my valve cover yet. The idle is every so slightly "cammy", but not rough at all. Vacuum is fine, this is a very mild cam.

Chuck Jones tried out a MP cam on his 2.2 TBI:

I installed MP's

"767" cam (.460 lift) into a 1985 Reliant SE. The car had no

EGR, 2.25in exhaust, K&N cone, a fresh headgasket. Ignition timing was

set at 12^ so el cheapo gas could be used. The car didn't really seem that

much faster, but it did scoot onto the freeway a little better. I spent a

weekend swapping in different cam keys and the butt-dyno liked +4 the most.

Gas milege didn't change, it idled better, but wasn't worth the money in my

opinion. Five speed cars might show a larger improvement. I put the

same cam/rocker setup into my '83 carburated Horizon and ran 16.4's with a 3.05

geared A525....

If I could do it over again, I'd go to the salvage yard and snag a '88 TBI

roller cam and call it a day.

Tried out a

camshaft yourself? Send the information in and I'll post it.

PN: P4349650

Cam keys are one way to adjust your cam timing. If you have had your head milled .20-.30 your cam timing will be 2 degrees retarded, you can either shim the head, reset the cam timing with cam keys or purchase an adjustable cam sprocket.

If your more into tweaking your car an adjustable cam sprocket is a good investment too.

Shelby retarded the camshaft 4 degrees in

the carburated Shelby Chargers with a special cam sprocket to make more high rpm

hp. A multi key-way sprocket for 82-87 engines was sold through Mopar

Performance but you have no way of telling where top dead center is! They forgot

to mark TDC on the sprocket for 4 of the key-ways.

1984-1988 "4201974" Square

tooth 2.2 Turbo, 2.2 N/A

1984-1987 "4201992" Square tooth hi-output 2.2 N/A

1989-1992 "4387557" Round tooth 2.2/2.5 Turbo, 2.2 N/A

1989-1993 "4448690" Round tooth 2.5 N/A "common block"

1986-1987 "4273238" Square tooth, "tall deck" 2.5 TBI ONLY

1988 ......... "4387535" Round tooth, "tall deck" 2.5

TBI ONLY

84-88 All 2.2 engines, Square tooth

............. (Gates p.n. T071)

86-87 2.5 tall deck, Square tooth ................. (Gates p.n. T114)

1988 2.5 tall deck, Round tooth ................... (Gates

p.n. T132)

89-93 All SOHC 2.2/2.5, Round tooth ......... (Gates p.n. T153)

91-93 2.2 DOHC 16V with Lotus head ........... (Gates p.n. T206)