N/A EFI shortblock

Since the majority of people are going to run what they have as far as shortblock goes this area is going to be fairly light! The typical 2.2 or 2.5 engine is stout enough for pretty much anything you can throw at it in TBI form. The 86-95 TBI engines have Light Weight connecting rods which can be considered bad for a Turbo engine, but for a TBI engine making 100-150 hp less this isn't an issue. Even if you modify you TBI so it's in the 150 +hp range the rods will have a long life at those levels. Indeed the engine will rev up faster with the lighter reciprocating mass!

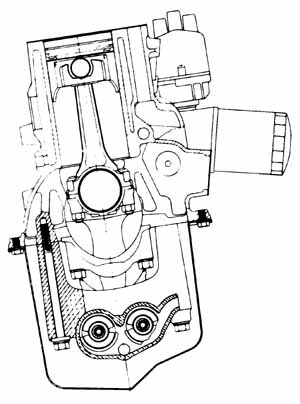

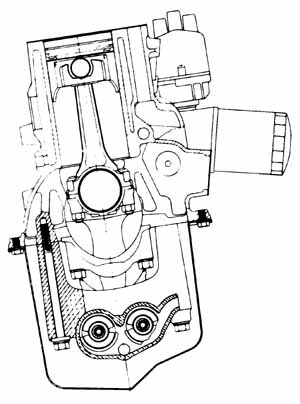

Here is a good view showing the differences between an 83-85 rod and a 86-95 LW rod. As shown in the first image, location "A" there is a 5 mm difference between rods. In the "B" Location there is a 7 mm difference. In the second image the width difference is 3 mm.

All TBI cranks are cast, the 2.2 crank is different then the 2.5 crank. The 86-88 2.5 "Tall Deck" motor has connecting rods different then any other Chrysler engine. In 1989 Chrysler went to the "common block" design and the 2.2 and 2.5 now shared the same block and connecting rods, the cranks changed with the common block engines and are not interchangeable with the earlier motors.

Recommendations-

1) If running the 2.5 remove the balance shafts for free power (see this link)

2) If running the 86-95 swirl head on a 2.2 you can raise your compression by using the 84-85 G-head pistons.

3) Follow all the tips in the lubrication section, there is some good hp to be found there.

4) Use light grades of Mobile 1 synthetic oil, thin oil uses less hp then thick!

5) When getting your engine rebuilt use a torque plate during the final honing to insure the bores are round as possible for maximum ring seal.

6) Consider getting your piston skirts coated for less friction.

7) Use the turbo rings- They cost more but are of higher quality and seal better.