Relentless- Race Season 2000

04/10/00

Well the K-car has been on a slim-fast diet the last 2-3 weeks. The car lost 230 pounds out of the interior last year and picked up 4 tenths, so this spring I started at the back of the car (where it's REALLY IMPORTANT for FWD) lightening it and moved my way forward from there! So far I have removed 200 pounds from the car and relocated 30 pounds from the rear to the front. I still have to get a rollbar installed so the car will be 10.00 legal when I'm finished. Here is a few pictures of the work in progress....

Here is the biggest hunk of weight in the back of the car- the 8 gallon fuel cell mounted in the trunk area. With 7.5 gallon's of fuel in it that's 63 pounds! (weight of cell, fuel, pump & lines)

Here is it's replacement- A custom made 3.5 gallon aluminum fuelcell mounted on the pass/front of the car. Not only does this lighten the car 43 lbs the remaining weight is on the front tires where it can do the most good. Also in the picture you can see the solenoid bank has been removed and a bank of resistors have been installed to fool the computer into thinking the solenoids are still there.

Here you can see where I relocated

the battery back to the left front (it had been moved to the right front,

now the fuel cell is there) It's a $24 235 CCA lawn tractor battery

(PN: UL1+) which saves 15 pounds over the Omni battery I was using.

More weight savings- The drivers door has been gutted (pass side was done last year) and the door glass has been replace with plexiglass. As you can see through the back window (also plexiglass now) I have been very busy with a holesaw....

A more complete list of work done the last few weeks...

hole sawed a lot of holes in

rear trunk/frame rail area (wore out 4 hole saws and one new drill)

gutted trunk floor and removed

fuel cell, floor replaced with 20 thousands thick aluminum

removed factory fuel lines

(4 pounds)

gutted and installed replacement

rear trailing arm (15 pounds)

new rear brake shoes and hardware,

milled dust lip off rear drums for weight savings

removed front bumper (need

to make aluminum support this week) 25 pound savings

gutted drivers door and added

aluminum door panel, replaced glass with plexiglass

removed factory door panel

on pass door (already gutted) and replaced with aluminum door panel

replaced rear bumper support

screws with rivets (weight savings)

designed new fuel cell, had

it constructed and installed in right front of car

installed new fuel lines &

pump in right front

installed relay for fuel pump

hooked directly to battery

made battery box in LEFT front

side of car below power module (of aluminum of course)

installed and secured 12 pound

235 amp lawn mower battery (17 pounds lighter them Omni battery I was using)

replaced steel bracket on

intercooler with aluminum

lopped off threads on various

bolts that were too long with sawzall (weight savings)

removed headliner (8 POUNDS)

removed an extra ceiling cross brace

replaced rear window with

plexiglass, saved 10 pounds

replaced solenoid bank on

pass/side shock tower with resistors (weight savings/looks neater)

removed pinch valve/regulator

setup (weight savings/looks neater)

removed hood insulation and

hood lamp & wiring

removed wiper motor and all

linkage

removed rear seat brackets

and bracing

removed rear seat aluminum

firewall (no longer needed due to removal of fuel cell from trunk area)

designed and had Epping track

officials approve new roll bar

Hoping to have car race

ready by April 30'th for Atco or Englishtown import battle...

04/30/00 Atco Dragway

Here is how my weekend went...

(THE TRACK CONDITIONS WERE VERY POOR)

The night before it rained, then the scraped ALL the rubber off the track, street cars were putting down lots of radial rubber down AND the track guys were using almost NO VHT to treat the track. All in all NO ONE was getting traction this saturday even the big boys.

8:15 passed tech inspection with flying colors

11:22 Pass number 1, no NOS Against Eddie Bergenholtz!!! Mr. Top Fuel Import!

I treed him by .010 and had a slightly better S.T. 1.76 vs 1.78 and it was door handle to door handle to the 330 mark (4.82 to 4.71) and then he just lit off like a rocket! at the 1/8 mile it was 7.4 to 6.9 and by the end of the quarter I had run a 11.7 at 113 to Ed's 10.5 at 141 mph! he picked up 31 mph from the 1/8 mile to the end of the track, the k-car only picked up 20.

Passes 2, 3 & 4 were 40 hp NOS runs

11.48, 118.9 mph, 1.83 ST

11.71, 116.8 mph, 1.92 ST

11.73, 114.1 mph, 1.96 ST

Car was breaking up badly as the day went on- EGT's were erratic and tried changing the fuel curve, cam timing and distributor timing had little effect on the car.

Pass Number 5, NO NOS

11.48 ET, 113.5 mph, 1.75 ST <-- cars best NO NOS pass to date

Pass Number 6, NO NOS (still trying to tune)

11.76 ET, 113.3 mph, 1.94 ST

Pass number 7, (Half NOS pass, 3rd only)

This was a fun pass- I was pitted against a RWD rotary Datsun with wheelie bars! I treed the guy with a .552 light but had a nasty ST of 2.02! his ST was a 1.5 but he was sleeping with a high 500 light. It was door handle to door handle again at the 1/8 mile 7.75 vs 7.6 and 9.96 vs 9.95 at the 990 mark. on the top end Mr. Rotary was starting to breath a bit and I wasn't putting up with any of that as I looked over at the guy and armed the NOS system and hit the switch Relentless won the race 11.94 at 117 to the guys 11.97 at 119! LOL! shame I had such a crappy launch...

Pass number 8.

11.56 at 118.9 with 1.88 ST.

This is the pass that broke the car- I leaned the car out because the EGT's were on the fat side to the tune of 1400-1450 or so. I was a little worried doing this because cylinder number 4 where the EGT probe is was showing signs of salt'n pepper on the plug even with the mixture pig rich! however I had the car up to 1650 last year with no ill effects so figured it was worth a try. Car pulled hard and the breakup problem gone! I was so suprised I forgot to hit the NOS trigger till I was well in to 3rd gear and the car was screaming down the track- EGT was 1600 through the traps and everything seemed ok till I got on the return road and:

1) right front slick was flat

2) slight skip

Went and got the truck, changed the tires and headed back to the pits. Car had a skip that came and went, number 4 piston is cracked but no too bad.

Things learned this weekend:

1) upgraded fuel system fattened up car- much shorter lines (by about 20 feet, lol) and higher voltage to pump richen mixture up.

2) Turbo and exhaust manifold hurting car performance- based on weight loss car should have picked up several mph but did not, exhaust manifold and turbine wheel raising backpressure to extreme levels preventing car from running better mph. Even upping the NOS from 40 hp to 60 hp did not raise NOS mph from 118. Time to pitch turbo and manifold.

3) coolant flow problem with cylinder number 4 needs to be addressed- even when fuel curve was pig rich (1400F EGT) and fuel octane was raised from 110 to 115, cylinder 4 spark plug showed evidence of detonation. I have an idea to fix this that's so stupidly simple its a wonder no one has though of it before... (perhaps someone has and isn't telling ? =)

4) S-60 turbo can hit 32 psi

(whoa!)

05/30/00

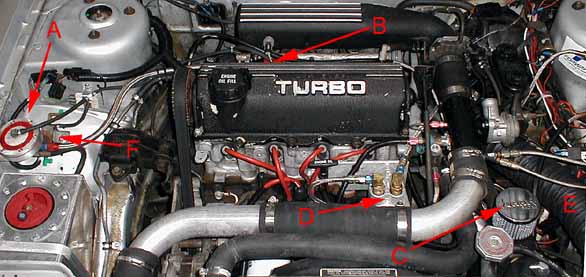

The time for fooling around has passed- the car is running again (as well as one can with a patched together shortblock, new forged pistons are not in yet) and there is a race to be run on June 3rd and 4th down at Englishtown. Take a look at what I have done...

A. Pinch valve to

help regulate fuel pressure

B. Adjustable fuel pressure

regulator

C. Breather & sump tank

for PCV & valve cover

D. Mobile one oil filter for

turbo (yes it has it's own filter)

E. Fresh air duct for turbocharger

(filter now mounted in front bumper area)

F. Solenoid for pinch valve,

fuel curve can be changed on the fly from within car during pass

Not visible is the Forward Motion Turbo and header nor the 52 pph injectors.

Also hard to see is this:

The water outlet for the cylinder head has been relocated to the end of the head- thus insuring that cylinder number 4 doesn't suffer from stagnate cooling anymore. You can see in the previous picture where the stock thermostat location is blocked off by a plate.

The compressor side of the turbo....

And the exhaust turbine side.. Big isn't it? =) The swingvalve is of my own devising. My MINIMUM boost with the wastegate can hooked to the intake is 18 PSI!

View from under car- The exhaust pretty much stops right to the right side of the picture, it dumps right after the rack. You can see the thermal sheet on the rack and exhaust pipe plus near the center of the picture is the support bracket for the turbo.

Made some other upgrades to the car as well, the 5th & 6th injectors can now be turned on and off from inside the car, trans service and valve body tweaking, plus some suspension mods...

June 3rd and 4th I'm heading

for Englishtown.. wish me luck...

06/06/00 Englishtown Dragway

Headed down friday night and was at the track first thing saturday morning, car breezed through tech inspection (How fast does this thing go?!?!?, heheheh!) and then tooled back to the pits to get ready. (temps were in the 70's with 45% humidity)

First pass the car blew out the right front slick and I had to swap out one in a hurry, instead of putting both the old slicks on I just replaced one so there was one new slick on left, one old slick on right.

so the first two passes were shakedowns to check the fuel curve, launch and anti-squat gizmo. the second pass was a 11.48 at 116, there was only one tiny problem- due to the differently worn slicks one was a little taller then the other and the car handled funny (an understatement) I don't recommend doing it! car felt like it was kicked at a 45 degree angle when I lifted off the gas at the top end! I still didn't have time to swap on the other old slick so they were even and made my last time shot of the day- with the boost set at 32 psi the car ran a 11.24 @ 121.99 mph on a 1.88 ST! man it was hair raising on the top end of the track! after the time shot was over I swap on the other slick and made another pass which was a 11.43 at 122 with a 1.98 ST (the larger turbo is taking some getting used to out of the hole)

The car had been a tad lean on this pass and had a bit of a slight skip, (you know what that means) Steve Adley, Dave Skrab, Anthony Berge and myself ripped into the motor and replaced 2 of the pistons in 4 hours flat in the middle of the pits with hand tools! Piston number 3 was cracked and piston number 1 it looked like the crown of the piston was lifting off!!!! People were looking at us in amazement as we went to town on the sucker, they couldn't believe we were fixing the car on the spot. They were really amazed when they found out how stock the engine was!!! I popped out the rod bearings to show one guy the 1989 date stamp on the bearing shells!

THE COOLING SYSTEM MOD WORKS. ENOUGH SAID.

Anti-squat gizmo seems to work, have to be careful on top end lifting off throttle.

Sunday on the first pass Relentless rapped off a 11.14 at 122 mph with a 1.86 ST! hoping to get a 10 in I went back and tried again- the car was to rich downstairs however and bogged of the line and ran a 12.5 at 121 mph with a 2.6 ST (whoops) next pass was a more careful 11.6 at 118 with a 2.0.

After some tweaking of the extra injectors so they came in later and a swap of spark plugs (I was still running the ones from yesterdays engine rebuild) it was off to stage for the first round of brackets- I dialed in the car with a 11.5 and was pitted against a cummings diesel ram with a 17.7 dial in- a sandbagger if I ever saw one. I was under the tower waiting to pull up to the burnout box and when blipping the throttle noticed the k-car had a slight rod knock!!!! CRAP! well the engine didn't owe me nothing so I went up did my burnout and staged. The guy in the truck took off and I mashed the pedal to the floor and waited for my lights-

and waited-

and waited-

and waited-

and waited-

6.2 seconds to be precise,

it felt like eternity- I was sure the car was going to drag itself through

the beams and red light me but nope like a trooper it hung in there and

I was off! at the big end of the track I was hauling ass on Mr. Diesel

and my closing velocity of nearly 50 mph panicked him as he broke out with

a 17.62. I lifted as soon as I approached the lights and coasted through

with a 11.42, breaking out less then him by the slimmest of margins...

8/02/00 Englishtown test'n tune night

Wednesday night found Heather and myself at Englishtown for a wednesday night test 'n tune- it was wall to wall street racers and imports! Time to open a can of whoop ass! The Reliant had a 1/2 hour of running time on the new engine so the first pass was an easy 22 psi of boost (the lowest setting for my new hybrid T3/T4 turbo) I can out of the hole fairly easy not know what to expect- the timing was set retarded 7degrees because of the new fastburn head (I was going to play with the timing a few degrees at a time- retarding it was a pre-caution due to the fast burn heads faster pressure rise) and I didn't know how the turbo was going to spool so I can out of the hole fairly lazy. The car ran 12.0 @ 113 mph with a 1.81 S.T. Everything looked good so the boost was set to 30 psi and I came out of the hole a little more aggressive and the car rapped off a 11.26 at 120.8 with a 1.76 S.T. I was STOKED! and this was with the intercooler hose popping off on the top end before the traps!!!!! Man I got 10's in the bag!!! run number three the hose popped off again in the damn burnout box!!!! Run number 4 the car launched ok but the car started breaking up BAD and THEN the intercooler hose blew once more! ARG!!!

Trailing the car back home I was wondering why the car crapped out on the last pass and when I did a check over the next morning I found the reason- Busted number 1 spark plug ceramic (OUCH!) While I was dwelling on this new problem I came to the conclusion that my double core intercooler was NOT flowing enough air and this was causing the hoses to blow off and it had to be replaced- yet how was I going to get one in time for the import race next week at Cecil County? DOUBLE ARG!!

While I was cruising the countryside clearing out every Peterbuilt truck dealer of the superdudybadtotheboneneverblowoff hose clamps a solution hit me- I would reinstall a FACTORY intercooler in the stock location and "Y" into the existing plumbing! YIPPEE! LOL! AND IT WORKED!!!

I should take a moment to describe

the new engine combo and what had changed-

A) New shortblock with J&E

forged pistons, shotpeened rods with ARP rod bolts and stock cast crank.

B) New design windage tray-

hangs off block now so I don't have to remove pickup to get pan off.

C) Forward Motion Stage III

ported cylinder head with IMSA valves

D) Remanufactured Torque converter

(old was was beat- I was losing 3-4 mph because of it!)

E) T3/T4 turbo with different

configuration

F) As of 8/05/00 extra intercooler

plumbed into system.

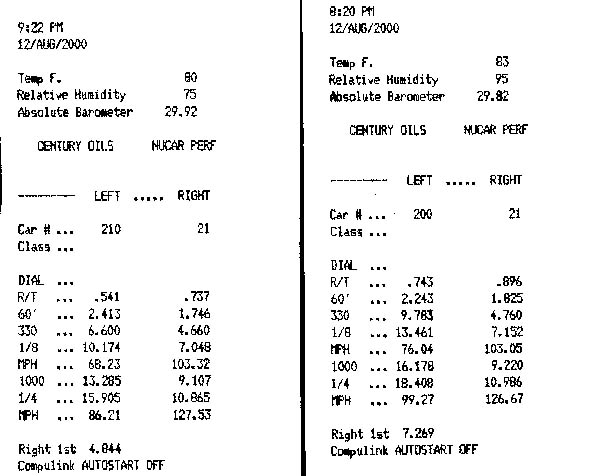

8/12/00 Cecil County Dragway

Well

we loaded up the car and Heather and myself headed south to Cecil County

friday morning- we were going to hit the track friday night for a test

& tune to make sure the car was running perfectly before stomping the

crap out of a pack of imports saturday morning... The very first pass the

car left HARD and was screaming when at the 1/8 mile the damn car blew

off a DIFFERENT hose! damnit! $%^$#^!! It was only pipe I didn't weld a

lip onto!! Steve Menegon and myself busted out a pair of vise grips and

a file and quickly bent a "lip" onto the offending pipe and reassembled

everything in a hurry (I wanted to get back out to the track, Cecil is

JAMMING on a friday night)

Aug. 12, 2000 7:14 P.M.

Relentless made a 10.98 pass at 126 mph with a 1.82 S.T! Man what a RIDE! The track feels like it's paved with cobblestones at 3/4 track (unlike e-town which is like driving on plate glass) and the car was vibrating so bad I could barely read the gauges!! I kept thinking "1450-1450-1450" as I watched the EGT gauge and tried to keep the car going in a straight line with the rear of the car dancing around! I swear I could hear Steve a'holloring all the way down at the far end of the track! He was hopping up and down like a 5 year at the starting line after the car broke into the 10's! He-he! The crowd went NUTS! I headed back to the pits to give the car a look over (and make sure all the intercooler hoses where still hanging in there) and wheeled back into staging... I dialed in a littttttle more boost and came out of the hole a tad more aggressive and the car clicked off a picture perfect 10.86 @ 127 with a 1.74 S.T. At that point it was time to call it a night, as I was loading the car for the trip to Steves place a gentlemen in a new 300 pulled up, rolled down his window and uttered the words that would make the night perfect-

"Man that is one BAD ass car!" =)

Amen

brother, amen!

And

the best part? No N.O.S!

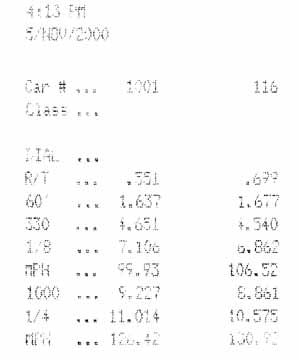

11/06/00 Cecil County

Well it was a rush job to make it to Cecil and when you rush mistakes happen (combine that with lack of sleep)...the new slicks didn't fit and different rims had to be obtained the morning we left for the event... the new datalogger that was installed in the car didn't work right due to a minor programming error because the programmer was rushed too but that's ok because the laptop fell off the roof of the car the day we were leaving...a spare laptop was grabbed from the house, robbed of it's harddrive at the hotel and installed in the damaged unit but it turns out a few of the OS install disks were corrupt so couldn't run the datalogger anyways which is just as well because of the software problem (datalogger displays live ram values as well, hardware and software will be for sale for a modest sum as soon as final programming is complete)...Made it down to the track and the EGT gauge failed on the first pass so I was unable to tune the car for track conditions! Was tempted to pack it up right then and there with Numero Uno gauge out of commission but figured since it was the end of the year the show must go on...

Run 1 (The easy pass)

The first pass of the day is always a shakedown to see what the track is like- I turn down the boost 1/4 turn, launch somewhat mild... you get the idea. I was somewhat suprised when I picked up the timeslip at the end of the track...The car "felt" so mild I swear it wasn't even a 10 second pass...

Short time 1.75

1/8 mile 6.90

1/8 mph

105 mph

1/4 mile 10.66

1/4 mph

129.6

Run 2

Lifted headgasket at 1/8 mile (remember, no EGT so I have no idea what's going on mixture wise)

Short time 1.73

1/8 mile 6.98

1/8 mph

100 mph

1/4 mile 11.7

1/4 mph

90.9

Run 3

Changed headgasket, checked over fuel system, found pinch valve which was fine for first pass now 35 psi low... backed off boost to be safe as well... aborted in burnout box due to water pump gasket failure caused by cooling system pressurization during run 2, pulled pump and repaired.

Run 4

Short time 1.73

1/8 mile 6.96

1/8 mph

102 mph

1/4 mile 10.84

1/4 mph

125.9

Run 5 (last run of day)

Nitrous bottle installed in car- doing the numbers showed that I need just 75 more hp to run a 9.90

Kit was set at 100 hp. Came out of hole very aggressive since track was biting, NOS triggered in 2nd gear.

Short time 1.67 <--

best to date.

1/8 mile 6.86

1/8 mph

106.5 mph

1/4 mile 10.57

1/4 mph

130 mph

Headgasket failed again in number 3 cylinder, car was breaking up almost whole pass, didn't care it was last race of year. Cylinder 3 having some kind of issue, rest of cylinders perfect.

No signs of detonation- hot spot in cooling system perhaps or lean injector in #3 maybe, have several ideas.

This winter some of the plans I have for the car are going to be shelved... I feel the car has an easy 9 second pass in it with minor lightening and refining of existing drivetrain- I haven't even maxed the turbo out yet! Just working on the fuel curve down low in the boost range has netted improvements in short time...

Catch ya later! 9's for sure next year!