Chrysler FWD Transaxles:

What they look like, what changed?

Manuals; 460, 465, 525, 520, 555, 523, 568 Clutches and Flywheels Manual Transaxle Gear Ratio Chart

1990 Manual Transaxle Application Chart

Preparing your manual transmission for racing

Proper installation of a manual transmission & clutch and break in

Automatic Transmissions; A-413, A-604

Preparing your automatic transmission for racing

Axle interchange and configurations

Transmission swaps to different years; what's needed?

Installing a 520/555/523/568 in a Shelby Charger or GLH (L-bodies)

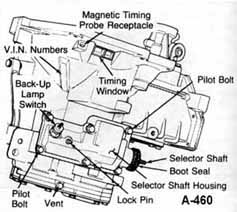

The 460 Manual Transmission 1981-1985

Chrysler's first transaxle for the 2.2 family of engines was a 4-speed. It had stamped steel shift forks and was prone to breakage if you beat on it too hard. (The forks and the tranny). The transmission was designed so that it could be easily converted over to a 5-speed later on if the market dictated the need. At the time of it's introduction all it's FWD competitors had 4 speeds so Chrysler felt that the extra $20 per unit for 5th gear was an unjustified expense.

The 465 Manual Transmission 1983-1984

For 1983 Chrysler introduced a transaxle with an overdrive; it was a 460 with a .72 ratio gear hung off the end of the input/output shafts. In mid '84 the junky stamped steel shift forks were pitched in the trash for better cast iron forks.

The 525 Manual Transmission 1984-1990

In 1984 the 525 was introduced; it was pretty much the same as the 465 except it was a close ratio for improved low and medium speed response. Shift feel was improved over the years as was durability by minor upgrades to the syncros, shift mechanisms, case and materials. Hi-po cars and caravans got stronger gears and shafts in some cases. The 525 was discontinued in 1987 for all cars except for the L-bodies. Externally it's the same as 465.

The 520 Manual Transmission 1987-1989

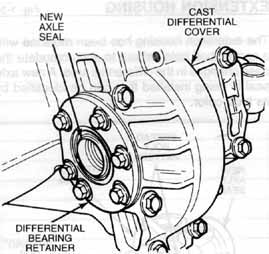

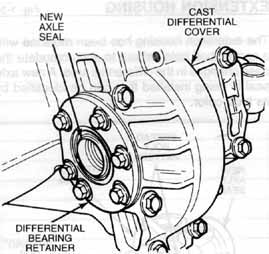

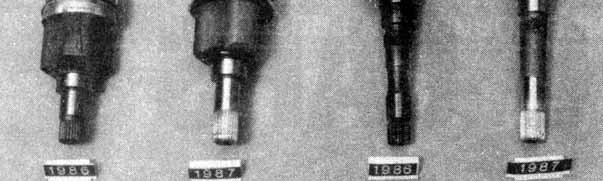

The first real improvement in Chrysler transaxles happened in 1987. The differential has always been a weak spot on the 460/465/525 and a redesign was done using a new CAD process to speed development time up. The new transmission was quieter and much more rugged. A new cast housing replaced the stamped steel cover for the differential and a redesigned ring gear with larger bearings helped vanquish ring gear deflection.

Also in 1987 the shifter and its cables were improved for better shifting and the axle shaft diameters were increased for higher strength. 5W-30 motor oil was the specified fill for all manual transaxles for reduced wear and increased load bearing capacity.

The new bad boy of transaxles was the 555; it was a 520 design with a heat treated case and a raft of high strength parts from Getrag of Germany. The most impressive was the differential case with its four pinion design, which Chrysler said was for "aggressive vehicle launches". This transmission was designed just for Turbo II engines. (It was also used in the 89 2.5 Turbo Caravan when ordered with a manual transmission)

The 523 Manual Transmission 1990-1994

Chrysler was really starting to become concerned with shift quality by now; they went all out to make the FWD transmissions shift as smooth as they could. Imagine a 520 transmission with a better shifter rail setup, add some low friction shifter cables and a even smoother shifter and viola' a new transmission. Shift effort is much reduced, but I tend to not like the rubbery feel the urethane cable ends impart on shifting compared to 89 555 cables. I'm told not all the cables have the urethane ends so your car may feel different.

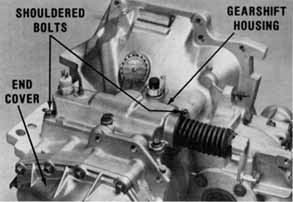

Notable changes besides internal syncro upgrades, four rail gearshift and three plane shifter, input shaft size was increased in 91, and the end case has been replaced with a trick looking cast cover for less noise and a stiffer transmission housing. The V6 version of this transmission is 543, it has a different bellhousing bolt pattern and some years have different gear ratio's. See the chart below.

The 568 Manual Transmission 1990-1993

The Ultimate FWD manual transaxle, basically a 555 with the upgraded syncros, cast 5th gear end plate, increased input shaft size (in 91) and 4 plane shifter rail setup. Some 568's have one other difference over the 555, it has the mounting tab and hole for a crank angle sensor used just in the 224 hp 16 valve engines. This transmission was used in all Intercooled Turbo vehicles (and some minivans) from 90-93.

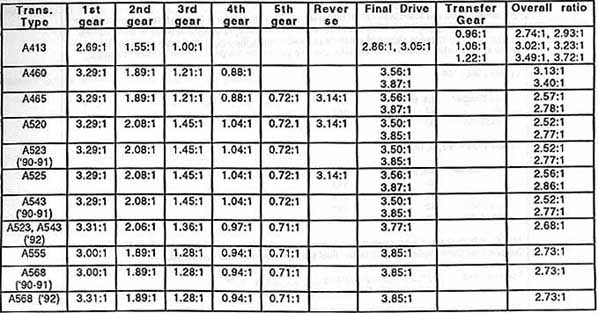

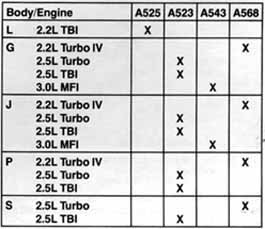

Transaxle Gear Ratio chart, courtesy of Forward Motion

1990 Manual Transaxle Application Chart

All turbo engines use a 230 mm clutch, as do all caravans (that I have ever seen) 2.2 carb and TBI use the smaller 215 mm clutch. There are 5 basic flywheels in the 2.2/2.5 family;

1. 82-85 6 bolt crank, small 215 mm

pressure plate pattern.

2. 84-84 6 bolt crank, large 230 mm pressure

plate pattern.

3. 86-94 8 bolt crank, small 215 mm pressure

plate pattern.

4. 86-93 8 bolt crank, large 230 mm pressure

plate pattern.

5. 91-93 16 valve 8-bolt/230 mm p.p. with

crank trigger slots.

Now a *great* upgrade for a carb or TBI car is to install the flywheel, clutch and pressure plate from a turbo vehicle. It's a direct swap in and the clutch will last just about forever.

Clutches are a hotly debate topic, quite frankly if your using a stock clutch its very good. However

sooner or later you will have to replace one.

Good clutches for mildly moded cars;

Brute Force series (Big A automotive outlets) Centerforce II, Stock Turbo II.

Clutches for those on the wild side of life;

Stock 91-93 2.2 16V & Mcleod Industries Rev-Lok.

Note: the stock R/T will work fine with any 91-up transaxle but the 84-90 transmissions will have to use a 84-90 Turbo II disc because of the difference in input shaft sizes. This is a hard combo for most people (84-90 vehicles) to get as Chrysler now sells the TIII clutch as a cover and disc set ($240) and people end up purchasing a disc they have no use for. The R/T combo is great for up to 300 hp, the Mcleod unit is good for *ANY* amount of hp you can throw at it- I have not heard a single report of slippage with this clutch.

It *IS* slightly noisy at times due to it's sintered iron construction and hair-trigger due to lack of cushion in the friction material but it's very livable.

NOTE: I have not tested the R/T pressure plate behind a 2.5 high HP engine. Play it safe and get the Mcleod!

Clutches with.... issues...

Clutchnet, some RPS units and Dealers Warehouse disc's

1) Clutchnet- Great disc's, seems to be huge issues with the *dual diaphragm* pressure plate not releasing in some applications & very short clutch cable life due to excessive plate pressure. Owners with functioning plates are known to carry spare clutch cables.

2) RPS- Great pressure plates, inconstant performance with discs. They come in several varieties (4 & 6 puck with or without alternating materials) with the 4 puck *full ceramic* disc being the only reported unit *NOT* to slip in high HP applications.

3) Dealers Warehouse sells pressure plates and discs. The Turbo III pressure plates are ok, the discs however have been coming apart like crazy even under *mild* combos. Avoid the Dealers Warehouse discs like the plague.

Clutches to be avoided at all costs;

Centerforce Dual Friction or any re-man.

DO NOT BUY THE CENTERFORCE DUAL FRICTION. I wasted $330 on this piece of junk and Centerforce would not even give me the time of day. It does not work under High boost/high torque applications. This has been verified by dozens of other hapless consumers in the Shelby Dodge Club, FMML and SDML.

I have tested all of the above clutches in many cars, the best bang for the buck was the stock R/T. What can I say? 5000 rpm launches with a 3100 lbs car on slicks making 300 hp. And it works day after day.

Proper

installation of a manual transmission & clutch and break in.

Do have the flywheel ground at a machine

shop

Do NOT turn the flywheel on a lathe

Do use a clutch disc alignment tool

Do NOT force a transmission on a miss aligned

disc

Do have clean hands when handling your clutch

disc

Do NOT get grease on the face of the clutch,

use brake clean if you do

Do use a torque wrench on the flywheel (65-70

ft/lbs) and pressure plate bolts (21 ft/lbs)

Do NOT use an impact wrench

Do loosen and tighten the bolts in a kris

cross pattern

Do make sure the dowel pin alignment bolts

are centered and tightened first

Do NOT crank in the upper bell housing bolts

first

Do fill the transmission with motor oil (10w30

is the factory fill)

Do NOT fill the transmission with ATF

Do lots of city driving for 750-1000 miles

at moderate throttle openings

Do NOT hammer on your clutch at 14 psi of

boost with 5 miles on it

The 568 is the ultimate manual transmission for FWD Mopars, followed by the 555, 523 and 520. As explained above, the 555 is about as strong as a 568 but doesn't shift as well and the 520/523 doesn't have the bad boy parts that the 555/568's have (although the 520/523 is still a *plenty* stout piece). The 465/525 is the weakest of the FWD 5-speeds but there is still plenty of people using them in their cars. Here are a few parts to help get the most from your 465/525/520/555.

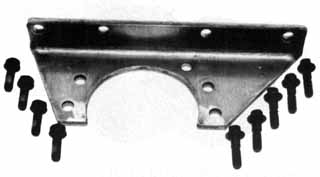

On the left is a Chrome Moly bearing retainer plate; the stocker is made from mild steel which will deflect under high horsepower loads and you end up breaking 3rd gear. I ran a 520 for 2 years with zero breakage using this plate- for $130 it was money well spent and can be used in any 525/520/555.

On the right is a differential girdle which helps prevent ring gear deflection on 465/525 transmissions.

On sure grips or posi style differentials I don't have to much information aside from they tend to be expensive ($500-$1000) but people who do road course racing tend to like them more them people who drag race. In drag racing you can balance or even preload the front end of the car to have equal traction on both tires where in a road course situation traction tends to move from wheel to wheel based on which direction your going! Its not unusual from a road course car for example to "light up" the left front tire on a left hand turn under acceleration due to weight shifting to the right side of the car. A posi will minimize this and make for a more consistent, faster car on the course.

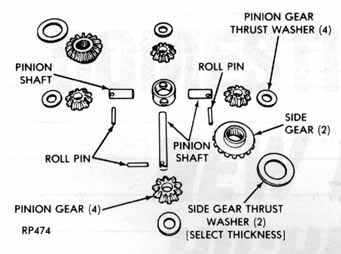

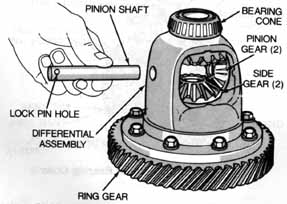

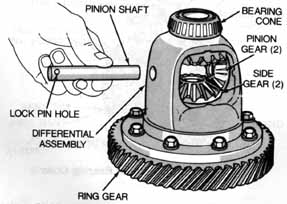

A on FWD transaxle spider and side gears- assume they are bad! If you have your transmission out for any reason, inspect the spider gears for gauling on the differential pin. I have seen them spin out the rollpin in as low as 70,000 miles! Usually the main diff pin will weld itself to the spiders and chew up the diff for a while turning it to junk before it really lets loose and spits out the case. Last time I purchased spiders, side gears, shims, and a new pin it was $120 my cost- cheap insurance for keeping your transmission in one piece.

Here is an EXTREME example of what will happen to a differential pin from doing one wheel burnouts. What's really amazing is that this damage occurred after only *TWO* trips to the dragstrip. This was a brand new pin and gearset that was installed in my Reliant when it was running high 11's.

A-413 Automatic, 2.2/2.5 & 3.0 V6

We will concern ourselves with the 84-92 model years here; This is a very general listing because I'm much more familiar with the manual transmissions.

84-85; 3 lug torque converter, 6 bolt flexplate, notches on converter for pump, small axles.

86; 4 lug converter, 8 bolt flexplate, flats on converter for pump, small axles.

87-92; 4 lug converter, 8 bolt flexplate, flats on converter, big axles with redesigned differential.

The Turbo & V6 cars tend to get extra clutches (but not all, I have seen some early turbo cars with carb/TBI pack setups)

The 84-86 transmission should be avoided, The torque converters tend to crack around the pump "ears" on 84-85 models which is why Mopar went to machining "flats" instead.

(Area that likes to crack)

The 84-86's also have the weaker differential

and axles which are more prone to breaking under high horsepower conditions.

The differential can be supported with a custom girdle but the money would

be better spent getting a 87+ transmission and swapping over to the stronger

axles.

Full manual reverse pattern valve body is great for full race or street cars; no wondering if the trans is going to shift at the right time or not AND you don't have to worry about going into neutral while shifting either because your going AWAY from it. That's why the shifting pattern is backwards. Another plus is the kickdown linkage is no longer used and can be removed.

SAFETY NOTICE- Turbo Action has been setting the line pressure far to low on the reverse manual valve bodies, please make sure you have 90-100 psi of line pressure. There have been several reports of the pressure being set at 50 psi.

Mopar Performance does make a shift improver kit, but its nothing a sharp transmission man can't duplicate in a small amount of time if he knows his stuff. Check out this image for a low budget shift kit.

There was a variety of different gear ratios & transfer gear sets made for the 413 over the years from the factory, a few of them are listed in the Mopar Performance catalog or you could just go digging in the factory parts books to find a combination that suits you.

Transfer gears-

0.91 (52 and 57 teeth)

(later L body)

1.04 (47 and 45 teeth) (Neon)

1.22 (60 and 49 teeth) (early L body with the VW)

In the factory service manual the following possible stock final drive ratios

are listed:

2.60 => 0.91 transfer and 2.86 ring

2.78 => 0.91 transfer and 3.05 ring

3.02 => 1.06 transfer and 2.86 ring

3.22 => 1.06 transfer and 3.05 ring

3.50 => 1.22 transfer and 2.86 ring

3.72 => 1.22 transfer and 3.05 ring

And for Neons:

3.19 => 1.04 transfer and 3.05 ring

2.98 => 1.04 transfer and 2.86 ring

There is also a variety of different factory kickdown levers with different ratios to play with so you can tune your band release/engagement to suit your needs.

A word on transmission coolers; get the biggest one you can find! There is no such thing as transmission fluid that's too cool and its an easy way to double the life of your transmission!

A on FWD transaxle spider and side gears- assume they are bad! If you have your transmission out for any reason, inspect the spider gears for gauling on the differential pin. I have seen them spin out the rollpin in as low as 70,000 miles! Usually the main diff pin will weld itself to the spiders and chew up the diff for a while turning it to junk before it really lets loose and spits out the case. Last time I purchased spiders, side gears, shims, and a new pin it was $120 my cost- cheap insurance for keeping your transmission in one piece.

Here is an EXTREME example of what will happen to a differential pin from doing one wheel burnouts. What's really amazing is that this damage occurred after only *TWO* trips to the dragstrip. This was a brand new pin and gearset that was installed in my Reliant when it was running high 11's.

A-604

4-speed Automatic (V6 cars only)

I have no information on the A-604 electronically controlled transmission at this time.

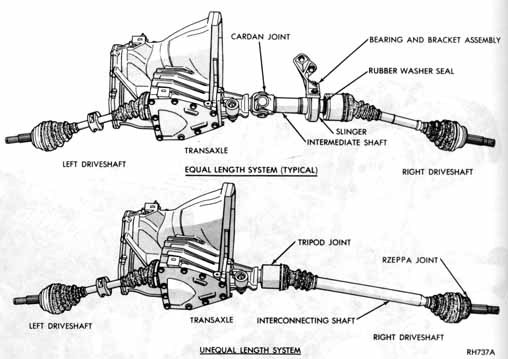

Axle interchange, configurations and equal length driveshafts

In 1984 Chrysler came out with its first turbo 4 cylinder; and it was good. There was one small problem though, the car under boost would tend to torque steer. This is a tendency of a car to "pull" in one direction while under power. Its caused in part by one axle being longer then the other and when the engine is under power the longer axle becomes a lever which pulls the car in that direction. Ma Mopars fix was to make the drive axles the same length by adding a intermediate shaft the was perfectly straight (in effect becoming part of the transmission) till the axle on the right side was the same length as the left. Axles are even interchangeable left to right. Most cars that do not have this system can be retro fitted to it as most 2.2-2.5 engines have the bosses cast into the block.

In 1987 Chrysler upgraded axles in all but the L-bodies to a larger, heavier splined axle (both automatics and manual transmissions)

83-86 small spline axles (weaker)

87-93 large spline axles (best)

All years had the same spline on the outer

end of the axle (at the brake rotor)

Just the inner spline changed as better

transmission were produced.

All G/H/K/J/AA/E axles are 100% interchangeable between bodies and years except for the years noted above due to spline changes on the transaxle differential end. The axles were made by several vendors over the years with the turbo cars having the strongest ones.

Automatic and manual transmission axles are 100% interchangeable as well.

In general L-body axles are unique to themselves and did not change till the 88-90 model years. When the car was equipped with an automatic transmission (1988-1990) it got the later style axle ends but retained its unique length. The car continued to use the 525 manual transmission for those years but still had the early model small spline axles.

Transmission swaps to different years; what's needed?

In this section we will cover what's needed to convert a 84-86 G/H/K/J/E (with notes for other years) over to a 520/555/523/568.

87-93 axles complete (intermediate shaft,

support bearing AND block bracket)

Later shifter and cables (a 84-86 shifter

can be used with some welding and modification)

If using a 520/555 you need a 87-89 shifter and cables (watch for different cable ends on some 520's- ball vs eyelet setup on one of the cables)

If using a 523/568 you will need a 90-93 shifter and cables.

Your current clutch cable will work fine except for the 523/568, you can replace your current cable with a later model one or respline the clutch arm so its in the correct spot.

Also 523 & 568's have a larger input shaft so you will have to replace your clutch disc if swapping over to one of them. All 465/525/520/555 have the same input shaft spline.

The "bobble strut" on the back of a 465/525 is in a different location then a 520/555/523/568. You will have to fabricate and weld new tabs onto the k-member (preferred) or use a long bolt with some spacers to attach the strut (not so preferred but it works)

If using a 523/568 minor grinding of the drivers side motor will have to be done to make it fit but all the bolt holes will line up no problem.

One other problem with using a 86 and up

transmission in a 1984-1985 car is you will have to replace the starter

due to the fact Mopar changed the way 2 of the bolts go in. Pick up a 86-up

starter while your in the boneyard (make sure you use the factory

heatsheild)

The weak link in the L-bodies has always been the transmissions- Chrysler never installed the better manual transmissions in these cars because their unique engine bays were extremely tight (and they were considered economy cars, it costs big bucks to do tooling changes which has to be spread out over a large number of cars to make it worth the money). But it can be done...

The transmission itself is a bolt in- on the 523/568 you will still have to do minor grinding to fit the drivers side motor mount just like the other cars. The tough part is the axles because Chrysler never made the large spline/manual trans combo for the l-bodies! There is two ways around this...

1) Purchase TWO 1988-1990 L-body AUTOMATIC axles and use any 87-93 G/H/K/J/E intermediate shaft.

2) Purchase ONE 1988-1990 L-body Automatic axle for the driver side. On the passenger side you will still have to get a 87-93 G/H/K/J/E large spline intermediate shaft but what you will do is just use the part the goes into the transmission. Take your old intermediate shaft and knock off the part the goes in the transmission (at the u-joint), swap over to the large spline unit, viola' hybrid part allowing you to use your old passenger side axle!

For the shifter a Shadow/Sundance unit seems

to have the right length cables and correct bend in it (get the one the

corresponds to the transmission your using of course) bust out the holesaw

and pop a hole right in front of the console and slightly to the left and

your good to go.

The bobble "shock" at the rear of the transmission

will now not line up correct- You can either get a new tab welded on in

the correct location OR use a long bolt with a spacer (to keep the tabs

from collapsing) through the original tabs in the k-frame.

Both have been used with good results.