Mopar Performance turbochargers

Mopar Performance USE to sell 2 turbochargers called the "Turbo Plus unit". It was nothing more then a stock Turbo I or TII turbocharger with a .63 ratio exhaust housing. Claimed hp gains were 6-7% with some loss of torque at lower rpm's. The 84-87 Turbo I part number was P4452780 and the 87-89 Turbo II part number was P4452781.

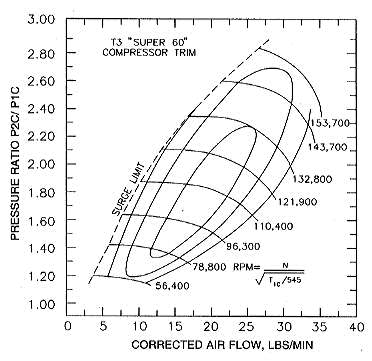

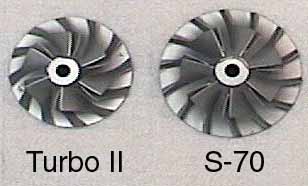

Mopar Performance also sells a Turbo II turbocharger as part of a kit (P4529980) known as the Super 60 package. The kit consists of 52 pph injectors, a 3 bar map sensor, and a S60 turbo (You also need the S60 computer to use the injectors & map sensor BTW). What is a S60 turbo you ask? Its a Turbo "Plus" unit with a larger compressor wheel.

S60 specs:

Compressor housing A/R .42 Exhaust housing A/R .63 Compressor inducer 48.5 mm Compressor exducer 60 mm Exhaust turbine diameter 48 mm

If you don't wish to purchase the whole kit, S-60 turbos (along with a wide variety of other turbos) can be purchased from Turbonetics. Again even more so then the regular "plus" unit this turbo in a 2.2 daily driven situation will feel very laggy compared to a stock turbocharger. The ideal combo for a 2.2 engine & daily street use IMHO is the S60 compressor housing & larger wheel with the .48 exhaust housing BUT this will limit you to 250-270 hp. The .63 housing is REQUIRED for 270+ hp!! Clipping the wheel or installing a larger turbine wheel will not remove this obstacle, this has been proven time and again on the dyno. The 2.5 engine on the other hand responds well to the S60 turbo and its larger exhaust housing due to the fact the 2.5 engine has torque to spare and has higher exhaust flow demands. The .63 S60 turbo installed in the K-car with its 2.5 engine was good for 3 tenths over the stock TO4 I was using.

The S70 turbo was something that was not offered by Mopar is any form but was more of an option by several turbo builders using "off the shelf" parts. It typically combines a stock Buick Grand National compressor wheel with a modified .42 compressor housing. It flows more then stock of course, but the downside is with the larger wheel sizes it increases lag and puts more load on the turbo bearings increasing the chance of bearing failure if the turbo has not been balanced correctly. The compressor inducer/exducer sizes are 50 mm/70 mm.

There are also a large number of

other exotic combinations of compressors/exhaust turbines not listed here.

Contact or visit one of the manufactures listed above to find out what fits your

cars needs and your budget.

About compressors,

intercoolers, exhaust housings and turbines...

If your not using an upgraded intercooler your not getting full use of your new

turbocharger! Testing in the last year has shown massive gains in performance by

increasing the flow rate of the intercooler core but almost NO gains by going to

a larger compressor while retaining the stock core. Even increasing the thermal shedding

ability of the stock core by converting it over to water-to-air has shown me no

gains. In short- Upgrading your turbos compressor without upgrading your

intercooler has minimal benefits. (unless your using a mitsu of course and you

should have upgraded to a Garrett a long time ago!)

Upgraded exhaust turbines however are a different matter...

What your looking at is advances in technology. The turbine wheel on a factory Garrett turbo was designed sometime in the early 70's at best. Compare that to the VNT turbine on the right developed later you will see that the VNT piece is lighter and more aerodynamically shaped.

Now check this out-

Close-up of factory Garrett 48 mm turbine vs. 64 mm stage III wheel that's on Relentless. Look at those blades! It's like comparing a paddlewheel to a airplane prop! Better flowing and lighter! Remember if your turbine and housing doesn't flow it's doesn't matter how good your compressor and intercooler is!

Exhaust housings or turbine scroll housings

There are TWO housings available for the SOHC 2.2/2.5 engine. One is the factory .48 A/R housing, the other is the .63 A/R housing shown above from Turbonetics. Turbonetics makes them because they were the contractor for the S-60 turbo from Mopar Performance. What's great about it? Well for starters it's flows better then the factory .48 housing so it will support more HP. What's the downside? Less exhaust velocity when not in boost = lag. Want to make over 300 hp without your exhaust manifold backpressure going through the roof your going to need one of these. 2.5 Engines REALLY like them when the rpm's are in the upper range! The larger 4-cylinder really puts this housing to good use and with the 2.5's fat torque curve lag isn't as much of an issue as it is with a 2.2.

There is also an operation called turbine blade clipping that allows the engine to breath slightly better by removing some of the material off the turbines blades. The theory is that it reduces the backpressure mimicking the effect of a larger turbine housing. In **our OHC application** the only effect turbine blade clipping has is to make the car more laggy and has almost NO effect on raising the HP level the turbine will support. The restriction is the actual .48 housing itself and clipping the blade or replacing the turbine wheel with a different unit has shown to have no effect on raising the amount of power the engine can produce. 270 hp is *about* the maximum the .48 housing will support with a SOHC and I have seen just under 300 hp with a DOHC with the wastegate welded shut.

Street car recommendations.

This is... very general..

If running a mitsu, intercool that sucker, then upgrade to Garrett.

If running a Garrett consider doing a better flowing intercooler before upgrading turbo.

At high boost pressures (20 psi+) the factory intercooler is the number one drag on the system. Replacing the single intercooler on the Reliant with a double sized cooler netted a 5 psi increase in boost with no other changes!

Upgrading from a Garrett that has a upgraded intercooler... In a heavy car with a 2.2 I would continue to use the .48 exhaust housing but look into a better flowing exhaust wheel and upgrade the compressor wheel at the same time. If using a 2.5 or a 2.2 in a lighter car both applications would do well with the larger .63 housing. 5-speed owners may or may not notice the lack of low end punch more then automatic owners. I will do a survey on this.

CAREFUL SELECTION OF TURBINE, COMPRESSOR AND HOUSINGS MUST BE DONE OR YOU WILL END UP WITH A TURBO THAT'S LAGGY OR JUST PLAIN INEFFICIENT.

It's really easy to get in a "bigger must be better" mentality- Don't. Here it's almost always better to go smaller and consult with an expert or two and check to see what other people are running and compare notes. It's one of the reasons this page is here, other peoples combinations will be listed so you can get an idea what to have built.

Full race, see below.

Hybrid Turbo's.

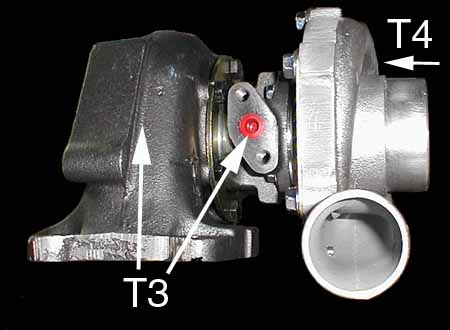

A hybrid turbo is a turbocharger that use components from different families. In this case, as far as FWD Mopars go (so far) Garrett T3 exhaust & center section (That's what our cars use from the factory) combined with Garrett T4 compressor housings and wheels.

Big Stuff.

Here is a page on installing a hybrid turbo on your FWD Dodge!-

Why is this important?

I have a theory about our little motors, it goes like this:

We have an engine that has 1 major problems and 2 minor ones- The major problem is a cylinder head with poor volumetric efficiency, the minor two are related to the factory intercooler and exhaust turbine.

The head & intercooler-

Well it's a 8V head designed back in the mid 70's you were expecting pro stock flow numbers? You can port if of course and increase the valve sizes but it's never going to flow like a 16V. So how do you get around this? Best thing to do is get a head cleaned up by an expert on Chrysler heads with a great valve job.

Then if you cannot make the ports flow more you have to pack the air in more tightly and make it more DENSE. Pack it more tightly by raising the boost, what's wrong with that though? Raising the boost raises the temperature making the air expand and making it less dense. So how do we make it more dense again? Better intercooler! Great! So now we are taking the hot boost out of the turbo and cooling it back down so it's dense again, so how can we improve on that even more? By not compressing the air so much in the first place! TIME FOR A BIGGER COMPRESSOR.

T4 sized compressors as a matter of fact.

Turbine and housing-

Great now we are cramming great amounts of dense air into the motor what's are next problem? Besides keeping headgaskets on the motor smart ass. Let me give you a clue.

This antique turbine wont let the

gas out! Time to replace it with something newer.

And I know you are using a .63 A/R exhaust turbine housing now.

Combinations

that work- Specs are important, pay attention.

Gary Donovan's Reliant. (10.66 @ 130 mph)

Car specs: 2.5 SOHC 8 valve engine, stock cam, header, stock 2 piece intake, IMSA valve ported head, triple core intercooler with automatic transmission (stock 86 Turbo I converter & 2.78 gears) weight 2250 with driver.

Turbo- (33 psi) T3 .63 A/R turbine housing with stage III turbine, T4 .60 A/R housing with 57 series compressor wheel. Uses modified factory swingvalve for wastegate.

Notes: Makes enough low end power to blow slicks away when equipped with 3.05 gears, shifted at 5500 rpm.

Dave St. Louis's 1988 Shadow. (12.05 @ 118 mph)

Car specs: 2.2 DOHC 16 valve engine, stock cams, ported head, intake and exhaust manifold, Spearco intercooler. Transmission is a 5-speed with 3.87 final drive ratio. Weight: 2870 pounds with driver

Turbo- (20 psi) Stage 3 (TA34) turbine wheel in T3 .63 A/R housing and a TO4E .50A/R T4 compressor housing with a 57 trim wheel. Wastegate is a Deltagate that is hooked to a custom 3in downpipe.

Notes: Spoolup is EXCELLENT. Dave's glad he didn't get the ball bearing option.

Stuff that's been tried and not worked all that great.

60 series T4 compressor wheel- Peaky and center of optimum use is 20 psi, very hot boost once out of it's island of efficiency. More a CFM wheel good for a 16V engine, a pressure wheel is better for SOHC.

Stage 3 turbine with a street SOHC 2.2 or application below 350 hp. The stage 3 will support over 400 hp- If your running a street car with less power then this you will have phenomenal amounts of lag and extremely slow building boost. Works better on a 2.5 application which has torque to spare and race only duties. It CAN be used on a SOHC 2.2 with the correct compressor and a high stall converter but again it's suited to RACE ONLY applications with a light car.

Stage 5 turbine- Lag city. Trades excellent exhaust flow for bad spool up. Nitrous-out-of-the-hole turbine.

T4 compressor wheel in stock compressor housing- The wheel isn't flowing as well as it could in it's native housing but still a marked improvement over the stock or near stock T3 family of wheels. Bill Bakers 2.2 SOHC Shadow generates 340 hp to the wheels with a TO4E wheel in a stock cover turbo.

Have a custom turbo? send in your information, facts, figures and impressions and I'll post it.

T4 compressor maps

(50 Trim compressor wheel)

(57 Trim compressor wheel)