Computer boost control.

You didn't think we were going to talk about this here did you? ;-)

I will tell you that trying to bleed the wastegate line while the computer is still controlling the boost is futile- Once you finally get the bleed open enough to get the boost where you want it for one reason or another you will disconnect the battery and the ECU looses it's memory. Then the first time you go for a road test you hit overboost like crazy because the computer "forgot" about how wastegate with the bleed was working! Oh and bleeding the map sensor to raise the boost? Don't do it. Your also leaning out the motor. Bad piston.

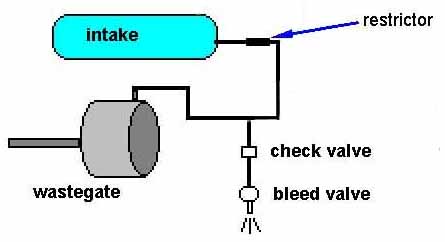

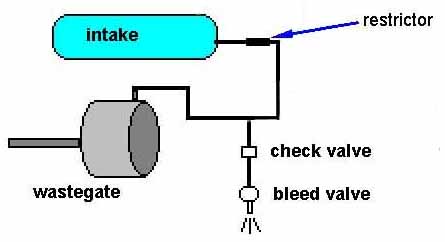

Simple bleed system

Doesn't get much simpler then this- The restrictor keeps you from having to have a MASSIVE bleed to open the wastegate enough and the check valve keeps you from having a vacuum leak when not under boost.

Problem- Boost goal may or may not creep past set point and spiking maybe and issue. Very sensitive to restrictor size, playing around with different ones came minimize problems and achieve desired results. Also boost pressure can prematurely start to open wastegate with this setup slowing spool time, not really an issue with most wastegate cans that have the heavy spring, could be an issue with some cars though.

Note- The bleed valve in this system can be mounted inside the car which is handy for fine tuning desired boost level. This is the system I'm using in the K-car, boost can be adjusted from a minimum of 22 psi to an unknown maximum (I have been as high as 33 psi)

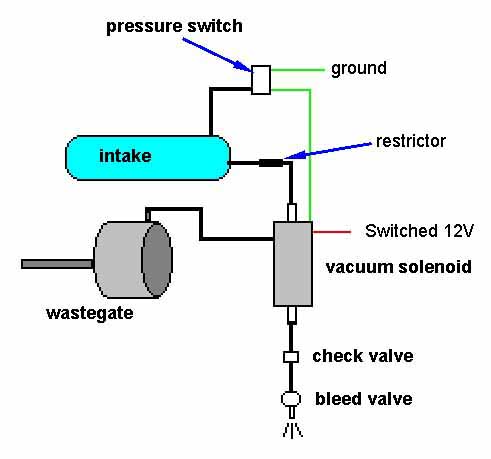

Modified bleed system with "anti-spike"

NOTE: The pressure switch is normally CLOSED.

When no voltage is applied to the solenoid, boost pressure runs directly to the wastegate.

This will leave you with 6-14 lbs of boost depending on load, rpm, throttle and how well your head/exhaust systems flow.

At normal rpms I see about 7 psi, at 5500rpm in 3rd or 4th gear boost will rise as high as 14psi (WOT)! This is due to a very high flowing exhaust system (3 inch, no cat, non-baffled muffler).

Now when 12 volts is applied to the solenoid, it creates a bleed to the wastegate, and in my case results in 18 psi of boost.

Here's the tricky part- when boost pressure rises higher than 18 psi, the pressure switch removes the ground path for the solenoid causing the wastegate to get full intake pressure and the boost drops off.

As soon as the boost drops below 18 psi, the solenoid come back on

and boost resumes again.

This happens so fast it appears as a slight flutter once or twice

in the gauge at max boost if you have done your job correctly.

Some trial and error maybe required to get your boost "just so" but

this is a very safe system if the pressure switch

is set to the max boost your engine can safely run.

Ahh the Grainger valve! (McMaster-Carr sells them as part number: 48935K25) Think mini air pressure regulator- hook one end to the wastegate and the other to the intake and your done! Set and forget. Want multiple levels of boost? Get two and hook them up with a solenoid and change boost levels with the flip of a switch!

Check out The Gus-miesters page on them- he covers in exquisite detail all the different ways they can be used and common problems that crop time to time when they are installed incorrect!

This is

really the best setup for the vast majority of turbo owners, no or little spike

& foolproof installation.

Gus Mahons ultimate boost controller.

Gus "master of the boost" Mahon has come up with another method of boost control. The basic skinny is you make your wastegate arm adjustable by cutting it in two, threading the ends and then installing a hex in the middle with a couple of lock nuts. The idea is to adjust the arm just long enough so that when you disconnect the vacuum line to the wastegate you will have the max boost you can safely run on your engine. What's happening is the backpressure in the exhaust manifold will get to a certain point and the wastegate will be forced open, shortening the rod will make the spring tension strong raising the boost, lengthening the rod will make it weaker lowering the boost. It would be very easy to add a solenoid that was switch operated inside the car to control this at will and have a low boost setting too. Check out Gus's page for all the details.

Some terms explained

Boost "creep" is when your boost goes beyond what you set it for- Lets say you want to run 12 psi and as your going through the gears the cars boost level starts to rise higher then you would like it to be. This is called creep. Most of the time this is caused by a wastegate that's not releasing enough exhaust gases to slow the turbine down or a artificially low boost level. As the cars load increases with RPM or load the exhaust energy increases too spinning the turbo even harder. Most of the time this happens by installing a higher flowing exhaust system on the car. How to fix this (cough) problem? The hard solution is to enlarge the wastegate hole so more exhaust flow can be diverted away from the turbine. This isn't a practical solution for most people. You could also reinstall the factory exhaust system to increase the backpressure in the system but that would be no fun ;-) The best thing to do is add more fuel to take advantage of the extra boost- If you hitting the computers overboost cutout point it's time to fool the map sensor using a diode or map Grainger. The only time I do not advocate this is when running non-intercooled. 14 psi is about the maximum practical limit for 94 octane fuel with no intercooler.

Boost "spiking" is when you shift and you boost level momentarily "spikes" to a few psi more then your set point. Your vacuum line size diameter, length and any restrictors can all have an impact in this area. Some experimentation maybe involved to minimize this.

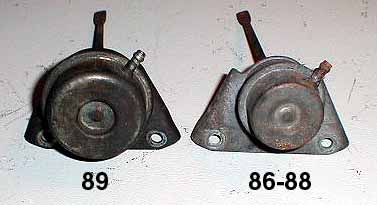

Another problem related to boost controllers is failure to achieve maximum boost. This is quite common on the 86-88 Turbo II cars with the small wastegate cans but can happen to others as well.

What Chrysler did those years was have a wastegate can with a very weak spring- If the wastegate line is removed and the engine is run the car will make only 14 psi of boost! (more or less) What is happening is backpressure from the exhaust manifold is forcing the wastegate open which of course reduces turbine speed dropping your boost.

The fix for this (assuming you want to run over 14 psi) is to increase the spring tension on the wastegate by:

1) Installing 1989 wastegate

can from a 89 TII motor. (Garretts only of course)

2) Increase the spring tension by shortening the arm.

3) Increase the tension by adding washers between the wastegate can and the compressor

housing.

4) Increase the tension by adding a extra spring from the wastegate arm to the

can.

All these will raise maximum obtainable boost level, proceed with care after making adjustments.

Dempsey Bowling has a marvelous page on homemade boost controllers and bleeds in general- stop on in and take a peek. He has everything well covered in superb detail.

Dempsey Bowlings

Turbo Performance Upgrades