A blow off

valve or shift valve is a device that allows boost pressure to be relieved

from the intercooler hoses

when shifting and the throttle blade is closed. This has two benefits:

1. Turbo stays spooled

up, there is no compressor slow down due to "stacking".

2. Turbo lives longer

due to boost not "stacking" up on the compressor blade.

Stacking is when the

pressure in the intercooler hose's is greater than the turbo output- that's

the noise you hear when you shift with an open element air cleaner, and

it's very bad for the turbocharger.

With a high boost

engine stacking is even worse!

A blow off valve is

NOT used to regulate boost.

The only Turbo Mopars that came with blow

off valves are 88-up Turbo I with automatic trans and some manuals, all

16V Turbo III motors. The only problem is they tend to rupture at 12-13

psi of boost! NOT GOOD.

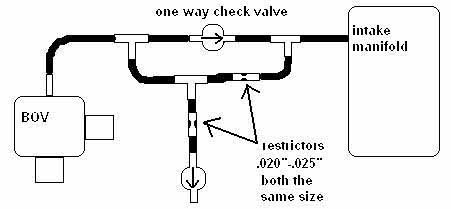

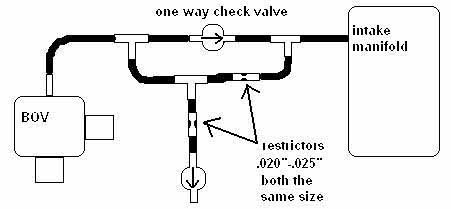

The first diagram is useful for anybody running a stock or Bosch BOV, or any BOV made of plastic. If you leave the factory's quick release valve in place, the stock BOV will lift off of it's seat and leak at 15 psi; the Bosch will lift off at 9 psi. If you leave the quick release valve out of the BOV line, the full boost pressure will eventually rupture the plastic housing and/or the rubber diaphragm. The pneumatic circuit below will send *part* of the boost to the BOV, but will still send full vacuum to it for a fast opening valve.

Here's what some of the aftermarket ones look like:

Gus Mahon describes his experience with blowoff valves:

If you get a Bosch blowoff valve from a SAAB, at first you'll love it, because it flows much more than the stock BOV. But here's what I found out the hard way: The valve blows off of the seat at 9 psi, so you have to counter act that by sending manifold pressure into the vacuum line nipple to aid the spring in staying closed under high boost. That worked fine, for about 500-1,000 miles. Then the unit ruptured!

The pressure in the vacuum nipple (23psi) makes the internal rubber diaphragm blow up like a balloon; the "balloon" then hits a sharp internal ridge. After a hundred "balloonings", the rubber gets cut through. The rupture lets lots of the precious boost leak out to atmosphere! The only way to counter the ballooning is to regulate how much pressure goes to the nipple. (about 15psi)

Go with the 1st generation (pre-95) Talon BOV, and it's MUCH better. It's all metal; no rubber or plastic showing anywhere. It doesn't blow off of the seat at 23 psi; that's the highest that I tested it for, so far. It's WAY more rugged than the Bosch unit!!

Mitsubishi PN- MR188465 OR Eagle PN- MD160689, It's an air bypass valve in the parts books.

They're about $90 new from the dealer; I found one for $69 new on the web; I bought one for $30 plus shipping from a DSM club member. Stay away from the Bosch... Go Mitsubishi!

Installed in Gus's Acclaim

Installed in my 89 Daytona Shelby.

I used the factory Mitsu flange and welded

it to my upper intercooler pipe.

See

this page on how to install one on your

car.

A Question from a reader!

Michael asked:

Now for the question, I am looking at the BOV stuff and notice that you have some sort of chrome muffler/aircleaner thing attached to the BOV exhaust hose, what is that thing?

Its a Moroso valve cover breather PN# 68811 with a K&N style element.

And is it necessary?

Sure is! When under

cruise or at idle the BOV is open to outside air! So some of the engines air

gets pulled through the BOV opening. Without a filter a lot of dirt and debris

would get ingested into the engine under these conditions.

On venting a BOV to the atmosphere VS the turbo inlet:

It's FAR

more important to get the air out of the BOV *quickly* to avoid spikes.

An open BOV tube will vent MUCH faster than a BOV with a tube attached.

That's why I vent mine to atmosphere. It's the way to go quickly. It's

the way to save your turbo's bearings.

This is how Gus attaches his BOV's-

This is how I mount the BOV on metal tubing that is part of the intercooler tubing. I use 2 part epoxy, and let it dry for a day without touching it. All metal surfaces to be epoxied must be shiny, rough, and clean. I use a grinding wheel on the metal just prior to assembly, and clean off the shiny rough area with alcohol.

Go visit:

Gus's Tech Pages

thomas.mahon@snet.net