Garrett

Turbo conversion by Gary S. Donovan

Did you know that the 84-87 Turbo I turbocharger is basically the same as the 87-89 Turbo II unit? It's a Garrett t3 with the same center cartridge as a TII but with slightly different exhaust and intake housings.

Be nice

to swap over an early Turbo for a Turbo II style would it not?

Make

it a lot easier to intercool it would...

Well,

sit back and let me show you how it's done!

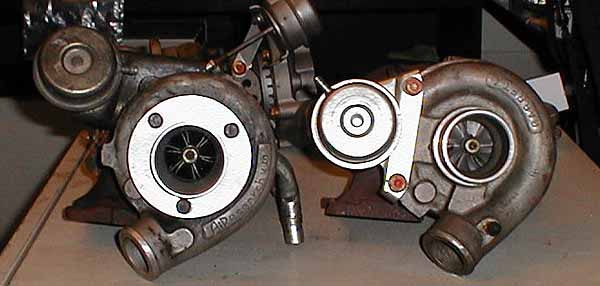

On your left is a 85 Turbo I and on the right is a 89 Turbo II.

List of things you need to do:

1. Grind notch in exhaust

housing to clear number 3 runner.

2. Weld shut or plug

EGR passage in wastegate housing.

3. Rotate compressor

housing.

4. Drill hole in wastegate

actuator bracket and remount.

5. Make adapter for

inlet of turbo.

I will

walk you through these steps one at a time.

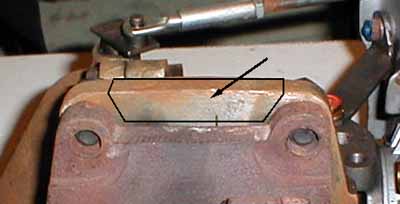

Step number one is grinding the exhaust housing to clear the number three intake runner. A bench grinder works best for this operation but I have seen people use a hacksaw, file or a sawzall in a pinch.

Grind

away the indicated area to clear the intake runner. Picture is of

an 85 and a 89 turbo back to back for a frame of reference, you could

also use any 87-93 turbo exhaust manifold to give you an idea how much

material to remove.

If you're using

an 84-86 vintage exhaust manifold now would be a good time to grind it

for runner clearance as well.

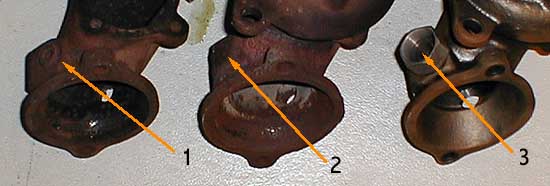

Step number two is plugging the EGR passage in the wastegate housing; there are a few ways to go about this.

# 1 is a simple hex head pipe plug screwed into the housing. DON'T USE BRASS.

# 2 is an 89 Turbo II housing which doesn't have any EGR opening at all.

# 3 is the factory fitting still in place which you can have simply welded shut if you cannot find a plug or cannot remove it from the housing.

Of the three

options #2 is the best for HP but most expensive. In 1989 Mopar went to

a 2.5 inch exhaust outlet compared to the earlier 2.25. If you go this

route you will have to find the larger exhaust outlet as well as a new

89-93 head pipe for the exhaust system. Extreme care must be taken

in removing the bolts from the exhaust housing as they get quite brittle

with heat and age, and like to snap.

Step number three is rotating the compressor housing so it's pointing in the right direction.

# 1 Remove the three bolts holding the wastegate can on and put the can aside.

# 2 Loosen the remaining four bolts holding the compressor housing to the center section, a turn or two is all you need. You may have to softly tap the housing with a hammer to break it loose so it can rotate.

# 3 Rotate the housing 48 degrees down; I use an angle finder gauge to do this. (I was just in a hardware store yesterday and saw that they carry these in the level section) You can eyeball it using the picture below or attach the turbo to the head for your car and rotate in the vehicle till it looks good and then lock it down.

Step four is easy, drill a hole in the wastegate can so it can be mounted on the compressor housing.

You cannot use an 87-89 wastegate can of course, due to the different configuration of the compressor housing, but that's ok. I have had one of these turbos up to 25 psi of boost so the early cans work fine. The 84 Turbo I has an odd dual port wastegate can, I don't know how well it will work. I'd replace it with a 85-87 TI unit myself, they are pretty much a dime-a-dozen at this point...

After drilling the hole, attach the modified can back on the turbo. It's a good idea to make sure that the can arm isn't rubbing on the number 4 intake runner, you may have to tweak the compressor housing angle or redrill the hole to make sure it clears. (the above turbo is missing a bolt in the upper left- just use the remaining housing bolt and a washer there)

Also the stiffening

bracket can be reinstalled if you wish, it's not pictured here.

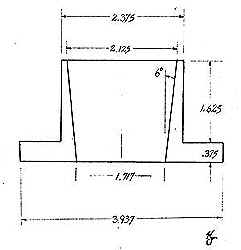

Step five, the last part is the hardest; you have to make an adapter for the air inlet to the turbo.

One way is pictured above, a friend of mine machined me one out of a piece of aluminum.

We have also made them by cutting off the 90 degree factory elbow and welding on a short piece of aluminum pipe from an electrical supply house. (2.25 inch conduit)

Or

you could do as one of my readers did- Piece of steel pipe and a good sized

washer.

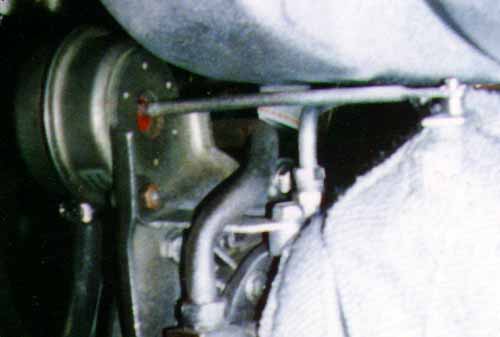

This is what it looks like when its installed on the head; note the clearance to the intake runners. You should have no problems using the stock Turbo I coolant & oil lines with the later one piece intake (I didn't). I don't know about a 2 piece intake, I haven't tried it.

Like two peas in a pod.

This is also

a very good upgrade for owners of cars using the small Mitsushitcy turbo

that Chrysler inflicted on 88-92 Turbo I owners. The Turbo II cars always

came with the larger Garrett. For the record my 86 Turbo Z was intercooled

using a turbo just like this and it ran 13.3 at 108 mph.