Installing extra injectors to support

more boost

Extra injectors at first blush sounded rather crude to me, and much like

the fellow in "Green eggs and ham" I resisted the idea at first.

Extra injectors just spraying in

fuel, how absurd! Was my thought, what about cylinder to cylinder

variations and rpm? That can't work! But Gus Mahon "a.k.a. Sam-I-Am"

persisted- "Try them, try them, you will see!" he said.

You know what? IT DOES WORK! Callaway

does it, as does Ak Miller and several other well known turbo kit manufactures.

In both of my cars 5th & 6th injectors

setups supply enough fuel to support over 30 psi of boost!

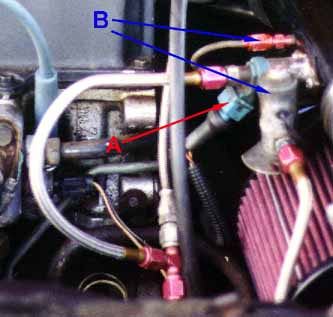

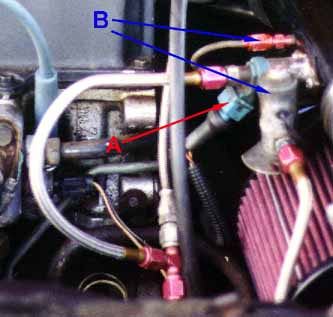

This is what I'm currently using. The intercooler plumbing is nothing more then 2' 1/4 exhaust pipe.

"A" is the 5'th injector

(a cold start injector from a Saab), "B" is an adjustable 6'th

injector using a NOS fuel solenoid and a fan spray nozzle.

The beauty of this

system is that injector B is tunable to any fuel flow you like by replacing

sized "jets" at the nozzle. (I got fancy and used mil-spec AN fittings

for fuel; its not required)

A popular question I get is

how do I get the AN fitting attached to the cold start valve? I take a Russell

fitting with 4AN on one end and 1/8 NPT on the other and lathe off the 1/8 NPT

and then run a die down where the threads were the same size as what's needed in

the cold start valve. A dab of sealer on the threads and I'm ready to go.

All you need is

to attach your cold start injector to the pipe with an o-ring and some

self tapping screws, tee into your fuel system (no leaks now) and hook

the fuel injector to a pressure switch and a power source. Adding a light

on the dash to tell you if your pressure switch is working or not would

be a real good idea too!

I get my pressure

switches at NAPA and they work great! They even sell ones pre-set to 15

PSI and they are adjustable to any pressure you want. The NAPA part number for the

Hobbs pressure switch is 701-1577.

NOTE:

The NOS solenoid shown above uses to much amperage to directly hook to

a switch, a relay was used to handle the amp load. If you are using a standard

cold start injector you will have no problem with the switch.

Here is a 5th injector installed on my buddy Jon's CSX-T that has 144,000 miles on it.

A) Is a pressure switch

set to 15 psi.

B) Is the injector itself.

The other photo is a picture

of a common Autozone 5/15 tee used to supply fuel to the injector. Still

using his stock Turbo I computer and injectors Jon runs 17-18 psi of boost

with no problems.

Fix engine, add more fuel (or

less boost), and as Benzo say's:

You hooked it up wrong and

blew it up... Be more f'n careful!!

And remember: The OEM fuel pumps are good to about the 260-270 hp mark, after that they just run out of steam. Adding extra injectors will not help!

Adding Extra Injectors

By Gus Mahon

(Article courtesy of Turbo Gearhead Central and Gus Mahon)

You can look at old VW’s, BMW's and Saabs in your local junkyard. On the intake manifold you’ll see that there are 4 injectors neatly in a row, and one more injector all by itself. The lone injector is the cold start injector. Cut off the fuel line with snips or cutters, and unbolt the two little bolts on the injector flange. It lifts right out, with no effort.

There's a banjo fitting on the top of these Bosch injectors. Leave it on, and leave the first couple inches of hard skinny fuel line on the banjo fitting. You can slip 3/16 ID fuel hose right over the 2 inches of line already on the injector, and clamp it on.

To supply fuel, you'll need to get brass fittings from NAPA to make a "tee" that has 5/16" hose barbs on each end, with a 3/16 nipple in the middle. You splice the tee into the rubber fuel line that feeds your fuel rail. I use 3/16" rubber fuel line to run from the tee to the injector. You can use metal line if it makes you feel better. Then connect the metal lines with short pieces of 3/16" fuel line and clamps.

The cold start injector has a nozzle that squirts out the fuel. Drill a hole into the intercooler tubing that's just slightly larger than the nozzle, then slip a half-inch long piece of fuel line over the nozzle. (5/16 ID) Lower the injector nozzle into this hole, and use it's flange as a template to mark where the 2 mounting holes will go. Then drill small holes to match the holes in the injector flange. When you tighten the two sheet metal screws into the holes you drilled, the fuel line will compress and conform to the shape of the intercooler tubing, making an airtight gasket. Now the injector is mounted.

You should have a pressure-activated switch turn on the injector at the boost level where you start to go lean. I can get the switches for $16 each. The polarity of the 2 injector wires doesn't matter; it'll work no matter which color wire goes to positive. Send one wire directly to positive, and have a pressure switch send ground to the injector at 14 psi or so.

Watch your rich-lean gauge; keep 9 lights lit on the gauge. If you don't have one, get one. Call Summit 1-800-230-3030 and ask for their digital Intellitronix Air Fuel Ratio Gauge ($29.99, free shipping)

Don't have it come on early unless your rich-lean gauge tells you it's needed. (8 lights or less) The extra injector will allow a couple of lbs more boost. That's when you really feel the difference. Flow rates of these injectors commonly support either 15 or 30 HP. Apply 12 volts to click them open, then blow through them. The ones that are slightly harder to blow through are good for 2 psi more boost (15 HP) The injectors that are slightly easier to blow through are good for 4 psi more boost (30 HP).