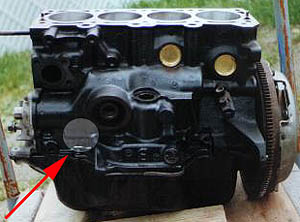

(Highlighted area showing fuel pump block-off plate used on 84-88 Turbo engines)

Shortblock

identification- Cranks, rods, pistons and other related stuff.

NOTE: The 89 CSX, Shelby Daytona and the Lancer Shelby are the only 'Shelby' vehicles with Turbo II internals. All 87-90 2.2 Daytona's marked 'Shelby' are production line cars with the HD 2.2 parts listed below except any 'Shelby Daytona' that was ordered with an automatic transmission, it received a non-intercooled 2.2 Turbo I which has the light duty parts. The automatics were NOT rated for the Turbo II's horsepower.

All other Shelby Dodge are Turbo I to Turbo II conversions performed by Shelby Industries at his factory in California.

Legit

TII have the best engine internals, in some cases overkill. Forged crank,

HD rods, Mahle cast pistons with floating pins and crossdrilled block and

heads for better cooling.

(Highlighted area showing fuel pump block-off plate used on 84-88 Turbo engines)

How to identify a 2.2/2.5 block?

Has oil & coolant return on back of block = Turbo

Has fuel pump plate = 1984-1988

No block off plate = 1989-1993

10 mm headbolt size = 1984-1985 1/2

11 mm headbolt size = 1985 1/2- 1993

Has cross drill in deck = '87-'90 2.2 T II/III/IV, '89-'93 2.5 TI, '90-'93 TBI

Has 6 extra boltholes in main cap bulkhead area= '89 2.5, '90-93 2.2, 2.5

Check date cast into block under p/s to further narrow down model year

Breakdown by year-

1984-1988

turbo blocks are basically the same except the 84-85 which had 10 mm head

bolts, 1986-1994 used 11 mm fasteners. (Note:

there were a variety of other small changes over the years- timing belts,

pulleys, sprockets, etc.. it's best not to mix stuff to much without checking

part numbers.)

The 84-85

block is ok- if you can have the block retapped by a machine shop for the

11 mm headbolts that's even better (for more clamping force to the cylinder

head for longer head gasket life). 84-88 vintage blocks are fine

for day to day use as long as power does not exceed 225-250 hp. (The blocks

lower end really flex around after that, this was fixed when the common block

debuted in 1989) ARP main stud's or billet cap's only put off when the block or

crank will break, not prevent it.

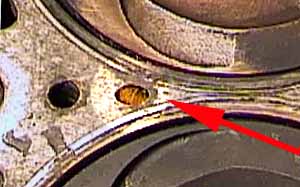

Factory

turbo intercooled engines built from 87-88 had cross drilling of the deck

and head for longer headgasket life.

Highlighted area showing lack of plate- 89-93 common block engine

In 1989 Chrysler introduced the common block engines- As the name implies all engines used the same casting and changes were made during machining based on what the casting was going to be used for. 12 pounds of extra material was added to the base of the block in the form of stiffer bulkheads and larger main caps to increase structural rigidity. A common block is a must for any engine making over 250 hp for any length of time otherwise broken main caps or crankshaft will be the result.

All Turbo

II and 2.5 Turbo blocks are cross-drilled, late 1990-1995 TBI blocks are

crossdrilled as well. This was done to promote longer headgasket life by

flowing coolant through the deck surface here engineers were able to reduce deck

temp's 75F degree's in this area. The TBI common block is the same as a turbo

common block except that the turbo oil return passage is not machined out

the rear of the block, a simple operation. Chrysler was able to get

2.5 liters out of a common block by using a 2.2 liter rod with very short

2.5 specific piston and long throw crank.

TURBO common

block 2.2's and 2.5's have different pistons and cranks- only the block

and rods are shared. I repeat this because people always forget.

The

2.5 Turbo/2.5 TBI block can be used as a replacement 2.2 TII block as long

as the oil hole for the balance shafts are blocked!!!! (2.5's always came with

balance shafts)

Jeff Chojnacki's Turbo II with head studs installed

Connecting

Rods

|

ROD |

ASSEMBLY PN: |

CENTER TO CENTER |

WEIGHT |

|

81-85 all 2.2 |

5203384 |

151 mm |

691 grams |

|

86-88 2.2 Turbo I |

4387736 |

151 mm |

659 grams- LW |

| 86-89 2.2 TBI | 4387736 | 151 mm | 659 grams- LW |

| 86-88 2.5 TBI tall deck | 4387733 | 157 mm | 669 grams |

|

87-88 Turbo II |

4323957 |

151 mm |

699 grams |

|

89-93 2.2/2.5 TBI |

4448999 |

151 mm |

659 grams- LW |

| 89-93 TI/II/IV | 4387699 | 151 mm | 699 grams |

The best rods to use are the TII ones (which require a floating pin piston) or the 81-85 2.2 rod (which do not). Basically the same rod except no bushing for a floating pin. All 89-93 2.5 Turbos use 89-90 TII rods. 91-93 2.2 16V engines use the TII rod with better bolts.

86-88 2.2 TURBO I rods are 30 grams lighter than the above rods and should be replaced at the first opportunity! They are not suitable for performance engines and will fail with no warning.

The 86-95 TBI rods are also not suitable for performance applications, however the 82-85 TBI/Carb rods are great replacements for pressed pin motors. Stock TII rods are safe to about 350-375 hp.

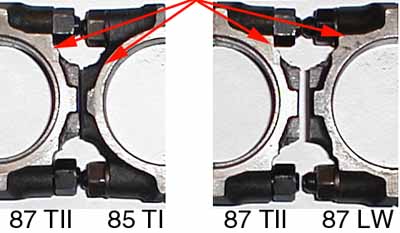

Here is a good view showing the differences between a early TI/TII rod and a LW rod. As shown in the first image, location "A" there is a 5 mm difference between rods. In the "B" Location there is a 7 mm difference. In the second image the width difference is 3 mm.

Something

to think about- The only difference between the TII rod and the 82-85 connecting

rod is Chrysler added a little meat to the big end of the rod for safety.

But as you can see on the right that they also added this extra meat to the

wimpy LW rod as well... Hypothetical situation... What if you had a set of beefy

early rods and a set of wimp LW rods... I don't see why you cannot use the LW

ends on the early rods and have a true TII rod.. Your going to have the rods

resized anyway in any good engine build up... I'm going to run the idea past my machinist

and see what he says..

Rod bolts- I have had very good results with the factory bolts in 300+ hp

engines with zero failures of any kind, however.... ARP rod bolts are good

insurance and can be installed by any competent machine shop.

Trivia question- Do you know what other mopar engine uses the same rod bolt as a

2.2? 318-360 V8

| 81-85 2.2 Carb & TBI | 92 mm stroke | 6-bolt | PN 5214737 | Cast |

| 84-85 2.2 Turbo | 92 mm stroke | 6-bolt | PN 4105498 | Cast |

| 86-94 2.2 TI & N.A. | 92 mm stroke | 8-bolt | PN 4343407 | Cast |

| 87-90 2.2 Turbo II | 92 mm stroke | 8-bolt | PN 4323815 | Forged |

| 87-94 2.5 TBI | 104 mm stroke | 8-bolt | PN 4323405 | Cast |

| 89-93 2.5 Turbo | 104 mm stroke | 8-bolt | PN | Cast |

Crankshafts- forged vs. cast. Forged is stronger but weighs 6-7 more pounds more than a cast crank! (The 2.2 16V Maserati forged crank is even worse- it's 23 pounds heavier then a cast crank) In any case I have never seen a crank fail. Garry McKissick has seen one of each fail so which one you choose is up to you. The cranks are interchangeable between Carb/TBI and turbo you just have to watch the production changes between years. Balance is unaffected; and due to the design of the 2.2/2.5 engines getting your 4-cyl balanced at a machine shop is largely a waste on time and money...

In my mind cast cranks are better because they are lighter allowing the engine to rev faster- I have had no failures even at 400+ crank hp... A forged crank might not be a bad idea in an early block application that's close to/over the 250 hp mark but this is only postponing the inevitable failure of the crank or main cap due to block twisting.

What bearings do I use?

Stock Mopar or Federal Mogul.

| Model Year | Manufacture | Type | Application |

| 1984-1985 | Chrysler | Cast | 2.2 Turbo I |

| 1986-1988 | Chrysler | Cast | 2.2 Turbo I |

| 1987-1988 | Mahle | Cast | 2.2 Turbo II |

| 1989-1990 | Mahle | Cast | 2.2 Turbo II/VNT |

| 1989-1992 | Mahle | Cast | 2.5 Turbo |

| 1991-1993 | Mahle | Forged | 2.2 Turbo III 16V |

I have used TRW/Sealed Power pistons with good results, the best CAST piston to use is the factory Mahle piston but that requires the use of rods which are set up for floating pins- Like the Turbo II or 2.5 Turbo I. (Piston vendors can be found on my vendors page)

NOTE: Common oversize Mahle pistons can be purchased for the 2.5 Turbo but NOT for the 2.2 Turbo II.

The best pistons to buy for a very high output engine are forged pistons from J&E or Arias. If you plan on buying it's a good idea to purchase J&E's from Forward Motion, they sell singles in case you have an "accident." J&E nor Arias will sell singles, just complete sets.

Not even the best forged pistons will survive if you ignore your EGT gauge.

A popular question I'm often asked is how much boost/hp can I safely run with factory cast or Mahle cast pistons? Quite frankly it's not how much boost is the determining factor but how much detonation! I have made well over 300 hp with cast pistons with boost pressures over 30 psi... If you run into even minor detonation at those power levels however.. you are the proud owner of a set of ashtrays.

(Joe O'Connor had a little detonation in cylinder #1)

Don't be lulled into a false sense of security because you have had experience with detonation at stock or near stock horsepower- most motors will come through with no damage at those power levels. At 300+ hp it's a hammer blow that will instantly destroy piston ring lands before you are even aware of the "death rattle". Go slow and watch your plugs for signs of damage. Forged pistons are a good investment and will tolerate occasional detonation at high horsepower levels but will break if constantly abused as well.

Be warned, the clips from floating pin pistons have been known to come out and score the cylinder wall. LRE has steel spring retainers that are safer. The is no horsepower to be found from floating pins- Sources inside Chrysler say that the floating pins were done for marketing reasons!

Here is a good warning! If you're getting your engine bored out, make sure the machine shop has the pistons on hand so the final bore and hone match the pistons. A GOOD machine shop will even number the pistons and hone each bore to the individual pistons measurements.

Stock rings work great as do Sealed Power replacements - Gapless rings have been tried on our cars with generally less then stellar results.

Piston Coatings-

(Dave St. Louis's Turbo III pistons)

There are a variety of skirt and top coatings for pistons- The Teflon coatings on the skirts reduce wall friction, coatings on the underside help shed oil and ceramic coatings on the top help reflect heat back into the combustion chamber and help protect the piston in case of excessive EGT temperatures.

Note: A

noted engine builder has warned me that coatings on the top of the piston may

protect the piston but will reflect more heat back into the engine making it

more prone to detonation.

Hyperutectic pistons for 2.2 and 2.5 engines

To be avoided at ALL costs on Chrysler turbocharged 2.2 &

2.5 engines. A snippet from the sealed-power

webpage-

"Contains 12.5% or more silicon content. Special melting processes are necessary to ‘super-saturate’ the aluminum with

additional silicon content. Special molds, casting and cooling techniques are required to obtain finely and uniformly

dispersed silicon particles throughout the material. Our hyper-eutectic material is also being used in light and medium diesel engines to

replace some of the eutectic pistons with iron groove inserts used for additional heat and wear resistance of the ring groove.

Heat and wear in the ring groove contribute to groove ‘pound-out. In the Sealed Power hypereutectic pistons, the hard,

finely dispersed silicon particles serve as ‘micro-inserts’ at the surfaces of the piston, especially in the surfaces of the

precision machined ring grooves. The increased strength, heat and wear resistance provided by the high-silicon content

hypereutectic piston material allows for elimination of the groove inserts in several piston applications."

Ed Peters, retired Chrysler failure analysis engineer did a study of hypereutectic pistons and this is what he determined..

1) Adding 8-16% silicon

reduces excessive material waste by 25% during casting (reduced flashing)

2) Piston reject rate is reduced from 3% to less then 3/10's of 1 percent.

3) Added silicon creates pores and voids in the piston.

4) Piston cannot handle the thermal loads a turbo engine exhibits.

In short there is no

performance benefit to making these pistons, it's all about reducing cost to

MAKE MORE MONEY.

Want to hear Ed

talk about it in detail?

You can download

the MP3 file here, it's only 460k and 2.5 minutes

long.

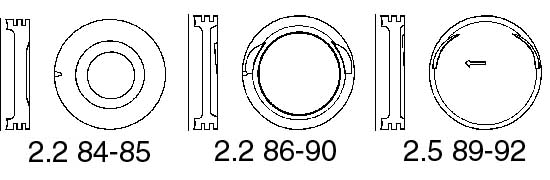

Some

technical data for those inclined..

|

Year |

Head Volume (approximate) |

Recess |

Compression |

|

2.2 1984-1985 |

9cc |

2.2" wide x .190" deep |

8.2 |

|

2.2 1986-1990 |

14.5cc |

2.6" wide x .190" deep |

8.2 |

|

2.5 1989-1992 |

unknown |

2.8" wide x .280" deep |

7.8 |

Piston tops and their chamber cc's

Want to see more pictures of Turbo I, II & III stock pistons? Click here.

Machining Operations

Sleeving-

There is nothing wrong with sleeving a block if some precautions are taken.

1) MAKE SURE THE MACHINIST USES A THIN WALL SLEEVE. This is very important!! When most machinists order a sleeve 9 times out of 10 a THICKWALL sleeve is what comes in. Make sure they specify a thinwall unit when ordering or the cylinder walls will be severely weakened.

2) No sleeves can be adjacent to each other or you will thin out and weaken the block so much it will crack after a few thermal cycles.

Boring & honing-

Make sure machine shop has pistons on hand for proper fitting during final cylinder honing. If they wish to final hone without having the pistons on hand, find another machine shop.

Torque plates-

Experts say that a torque plate (a device to simulate a cylinder head being bolted to the block) is needed when building a hi-po motor. During the final hone it's attached to the deck surface and the idea is you will have a perfectly round bore for maximum hp. On the 2.2 I have been doing a study of people who have used torque plates and in 50% of the cases there was no significant bore change when a plate was used or not used.

Dan Carson on torque plates-

Just about every book on performance engines recommends using a torque plate to make sure the cylinder is honed under the same stress loading that will occur when the head is on. That's a common approach in all performance engines. I think it's even more important in ours because of the high cylinder pressures and potential for blowby. Also, according to Ed Peters, our engines tend to have small areas in the cylinders that are pulled out of round when the head bolts are tightened. This occurs adjacent to each head bolt at about the height of the top ring-not a good deal for sealing. The doing it "right" part means that the bolts used for honing should be the same as the ones that will hold the head on and they should be engaged to the same thread depth as they will when the motor is assembled. Stick a stock bolt in the head, put on an old head gasket and measure what sticks out-that's the thread engagement depth you want (I know, head gaskets compress, but close enough:)). At that point you can either have stanchions cut or figure out how many washers need to be put under the head bolt to make it the right length for the torque plate.

ON bolts: ARP bolts are great, but they are too long and need about .150 cut off the end and need the stock Chrysler washer in addition to the ARP washer. Put them side to side and see how long those puppies are. Last thing is a recommendation to make sure your head bolt holes in the block are super clean before you try to assemble the engine. They should be so clean you can easily hand turn a head bolt into the hole. My guess is a lot of headgaskets go away because of bad torque reading caused by dirty bolt holes. Hey, hope this helps, Dan Carson