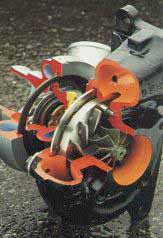

1984-1987 TO3 Garrett used on non-intercooled 2.2 (Turbo I)

(click for larger image)

| Application | Manufacture | Notes |

| 1984 Turbo I | Garrett/AiResearch | Dual port wastegate

can

2.25 exhaust donut/small flange |

| 1985-1987 Turbo I | Garrett/AiResearch | Single port

wastegate can

2.25 exhaust donut/small flange |

| 1988 Turbo I | Mitsubishi | 2.25 exhaust donut/large flange |

| 1989-1993 Turbo I | Mitsubishi | 2.50 exhaust donut/large flange |

| 1987 Turbo II | Garrett | 2.25 exhaust donut/small flange |

| 1988 Turbo II | Garrett | 2.25 exhaust donut/large flange |

| 1989 Turbo II | Garrett | 2.50 exhaust donut/large flange |

| 1989-1990 VNT | Garrett | 2.50 exhaust donut/large flange |

| 1991-1993 Turbo III | Garrett | 2.50 exhaust donut/large flange |

1984-1987 TO3 Garrett used on non-intercooled 2.2 (Turbo I)(click for larger image)

This Garrett turbo used on all 84-87 non-intercooled 2.2 liter engines. The 84 model year differs from the 85-87 models as it had a dual port wastegate can compared to the later models single port can. In 1984 the turbocars boost was set pneumatically, in 1985-1987 it was done by the computer for more precise control. Aside from this the turbos are the same. Boost was anywhere from 7.5 pounds to 10 psi depending on the application.

See THIS page on how to convert the Turbo I Garrett turbocharger to Turbo II configuration.

TO3 TI specs:

Compressor housing A/R .42 Exhaust housing A/R .48 Compressor inducer 42 mm Compressor exducer 60 mm Exhaust turbine diameter 48 mm

1988-1993 TEO4H Mitsubishi used on non-intercooled 2.2 & 2.5's (Turbo I) (click for larger image)

In 1988 Mopar went to a small, fast spooling turbocharger for their non-intercooled engines, boost was 7 to 9 pounds depending on the application. In 1989 the mitsu turbo received a larger exhaust outlet for better exhaust flow. My Mopar literature for 1989 states that the mitsu turbo used on the 2.5 had internal mods for more airflow, perhaps the larger exhaust housing is what they were referring to. No parts are interchangeable between the Garretts and the coolant & oil lines are different as well. The mounting flange bolt pattern is the same however (same exhaust manifold) and the exhaust donut is in the same location.

TEO4H specs:

Compressor housing A/R small Exhaust housing A/R smaller Compressor inducer 38 mm Compressor exducer 53 mm Exhaust turbine diameter 51 mm

(click for larger image)

For performance use I cannot recommend a stock Mitsubishi turbo AT ALL! It has a much smaller compressor, the shaft bearings are a third the size of a Garretts and the exhaust housing is a major restriction! The backpressure at high boost levels must be obscene, the picture above shows the difference in exhaust housing passage sizes. The mitsu's is about the size of ONE 2.2 exhaust port!

TI/TII Garrett compressor wheel on left, TI Mitsubishi on the right...

1987-1989 TO3 Garrett used on intercooled 2.2 (Turbo II) (click for larger image)

In 1986 (Shelby GLHS) Mopar introduced the 2.2 intercooled engine which used a modified TO3 Garrett turbo to supply 12 psi of boost. In 1988 the turbo's exhaust outlet was changed to a larger flange size and in 1989 it received the better flowing 2.5 inch exhaust outlet. The part number for the turbo's center section is the same as the TO3; the main differences is the compressor housings inlet and orientation, new wastegate can to match the new housing, a notch in the exhaust housing to clear the number three intake runner and lack of EGR port on the 87 and up applications. A/R ratios & wheel sizes remained unchanged.

An important thing to note if your planning on running higher then stock boost is Mopar did a sneaky from 1986 to 1988. See the wastegate can on the right? It has a spring in it that is so weak that if you remove the hose going to the wastegate you will only get 14 psi of boost!! The exhaust backpressure at 14 psi overcomes the spring tension in the can and bleeds the boost off. In 1989 Mopar went to a larger can with a much stiffer spring for more precise boost control, it allows MUCH higher boost pressure! ;-) more on that a little later...

See THIS page on how to convert the 84-87 Garrett Turbo I turbocharger to this Turbo II application.

TO3 TII specs:

Compressor housing A/R .42 Exhaust housing A/R .48 Compressor inducer 42 mm Compressor exducer 60 mm Exhaust turbine diameter 48 mm

1989-1990 VNT25 Garrett used on intercooled 2.2 (Turbo IV)

(Variable Nozzle Turbo)(click for larger image)

In 1989 Shelby introduced the 2.2 VNT powered CSX. It used a very unique Garrett turbocharger to combat the perception of excessive lag in day to day driving. The package consisted of three parts- part one was a physically smaller compressor wheel to promote fast spooling similar to the TEO4H Mitsubishi. Part two was a low restriction/low backpressure intercooler; it didn't cool as well as its earlier brethren but at 12 pounds of boost and premium pump gas it did the job just fine. The really unique part was the exhaust housing, instead of a conventional wastegate housing it had 12 movable vanes! The idea was to redirect the exhaust flow (using the vanes) at low speeds to promote fast spool up and then breath better at high rpm's by opening. 1990 was the only year they were used on production line cars.

You can read more about the Variable Nozzle Turbo right over HERE.

Check out detailed VNT pictures HERE.VNT25 specs:

Compressor housing A/R .48 Exhaust housing A/R .64 Compressor inducer 36 or 40 mm Compressor exducer 52 mm Exhaust turbine diameter small

1991-1993 TB03 Garrett used on intercooled 16V 2.2 (Turbo III)

(I know this isn't a SOHC turbocharger but figured it was good for reference)(click for larger image)

The TBO3 is part of the T3 family of turbochargers from Garrett. In this application the main differences are the larger compressor wheel and housing for better airflow (Turbo III engines are rated at 224 hp), and the exhaust housing which has a more "universal" flange pattern unlike the Turbo I, II and IV engines. Ford SVO Mustangs use a similar housing as well as one or two other auto manufactures. There is a wider variety of exhaust housing ratios available for this turbo because of this. It will NOT bolt to a regular SOHC exhaust manifold.

You could in theory have the slightly larger wheel and compressor housing swapped onto a TO4 turbocharger, but I'd imagine there would be some wastegate can issues along with the fact these turbos are relatively scarce. (from Mopar anyway) It would be cheaper to have a S60 or S70 wheel installed on your TO4 and it would flow more air as well.

TBO3 specs:

Compressor housing A/R .52 Exhaust housing A/R .48 Compressor inducer 45 mm Compressor exducer 60 mm Exhaust turbine diameter 48 mm

Throughout the turbo production model years, the turbine housing nickel content changed. The nickel content can be identified. There is a M# cast into the housing. The high nickel housings will have an M-4, while the lower nickel units will have M-3. The significance? Improved heat cycle capabilities, with the higher content housing. These housings can with-stand more thermal cycles and elevated temps. beyond the lower nickel housing. The turbine housing and the "turn-down" (exhaust outlet) both have these markings. A couple packages that benefited from this "durability upgrade" were the VNT's, 1987 T-II's, and some 1988 T-II's.

The VNT received an extra bonus. The VNT exhaust manifolds have a large 'N' cast into them. That is because they also received a much higher nickel content due to the excessive heat generation of the VNT system.

|

A/R .48

|

You know what?

He is dead on right. Went and peeked at a few turbos I have here

around the office. All the early turbos had "M26" cast into them, a rebuilt

89 TII had "M3" in both the exhaust housing and the outlet and my TIII

turbo had "M4" cast into it housing. That would explain why the early turbo

housings are more prone to cracking then their late model counterparts.

Thanks 5Digits!

Turbo stuff your mom warned you about.

First we are going to start with the general disclaimer- Your turbo was designed to operate within a certain boost range. Operating that turbo outside its range or "map" is called overboosting and can lead to a shorter turbocharger life.

Proceed

at your own risk.

One of the first questions a turbo owner wonders when he gets the itch to go

faster is, just how much boost can his cars turbo produce and how

high can I go? Here is a chart based on my personal experience.

|

1984-1987 Turbo I Garrett |

20+ psi with alcohol injection or an intercooler |

|

Modified Turbo I Garrett |

26+ with intercooler & race gas. See conversion page HERE |

|

1987-1989 Turbo II Garrett |

28-30 psi with intercooler and race gas |

|

1989-1990 VNT |

Less then TO3 due to smaller compressor |

|

1991-1993 Turbo III |

unknown |

|

1988-1993 Mitsubishi |

20-21 psi with intercooler |

|

S-60 with 2.5 engine |

25 psi with stock intercooler, 30 with large intercooler, race gas |

This is based on my "hands on experience" so far I can honestly say I have not had any turbo failures related to running these turbos outside there rated specs. HOWEVER I'm careful to use Mobile 1 motor oil at all times, I let my turbocharger cool down after spirited driving, I have a blow off valve (see BOV page) and perhaps I have a bit of luck on my side after all these years.

The candle that burns at both ends burns twice as fast, but at 30 psi it burns pretty damn bright.

Running your turbocharger outside its rated boost range also voids it warranty. 'nuff said.

Ready to

start making

BIG POWER?

Head over to..... THE ADVANCED TURBO PAGE.

Thanks for visiting Donovans Dodge Garage